外文资料--General Design Introduction

3页1、Geneal Design IntroductionGeneral Design IntroductionThe last 20 years. With the rapid development of Chinas manufacturing industry. Various processing equipment was widely used in the processing industry. Therefore, the equipment manufacturing industry has been an unprecedented development. With Chinas economic restructuring and upgrading manufacturing technology, the original tradition, a single general equipment Sijing can not meet the needs of the market. Thus, the NC-based semi-automatic an

2、d automatic access to a large number of Chinas advanced equipment market.In the 1980s and early scores. Chinas machine tool manufacturers began developing many trial production with its own brand of CNC milling and processing centre, and with this supporting feature also emerged(Such as the spindle, rails, ball screw, bearings, etc). At this time, the development of CNC machine tools has a related conditions. Various manufacturers have also launched its own branded products, and their respective

3、 characteristics and a price advantage, and imports of machine tools in the competition seek survival. After more than 10 years of development, Chinas CNC milling and processing centres have made great progress, whether it is performance, accuracy, or the types and packaging, have reached a considerable level of general machine tools have been accepted by users .The CNC machine tools, in particular, to do high-speed processing of NC machine tools, the overall structure of the machine should take

4、 full account of the processing machine object, processing characteristics and application of the machine itself to a reasonable structure. High-speed processing machine parts should be structured to meet the rigid, light weight, the dynamic characteristics of good requirements, as machine tools targeted at high-speed processing, so the NC machine tool axis and the various moving parts will be frequently changed the direction of movement. This will have a significant impact arising from inertial

《外文资料--General Design Introduction》由会员枫**分享,可在线阅读,更多相关《外文资料--General Design Introduction》请在金锄头文库上搜索。

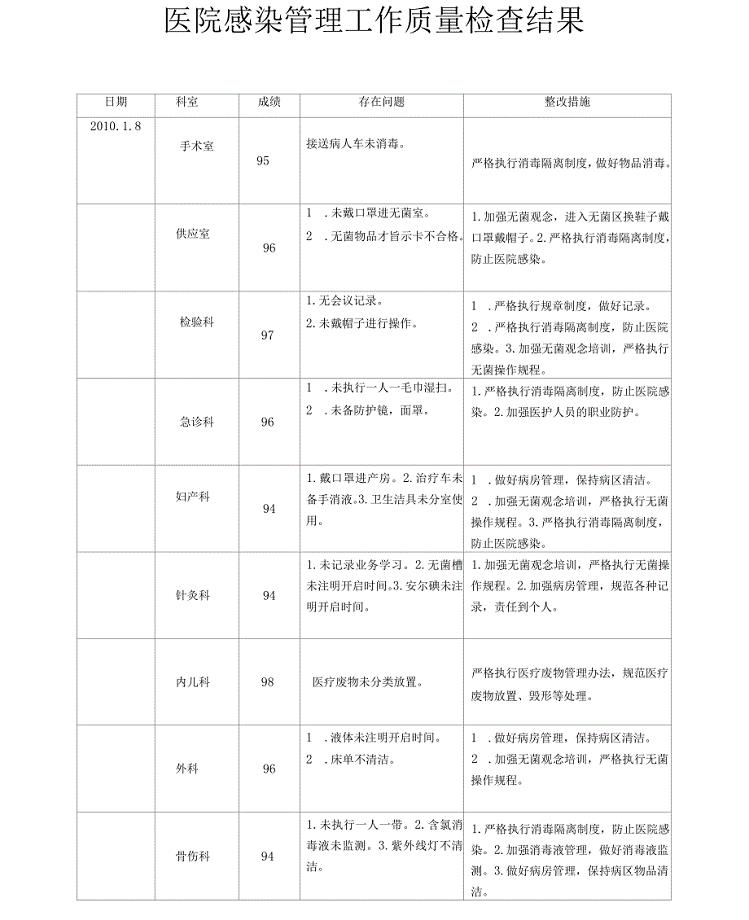

院感质量检查结果

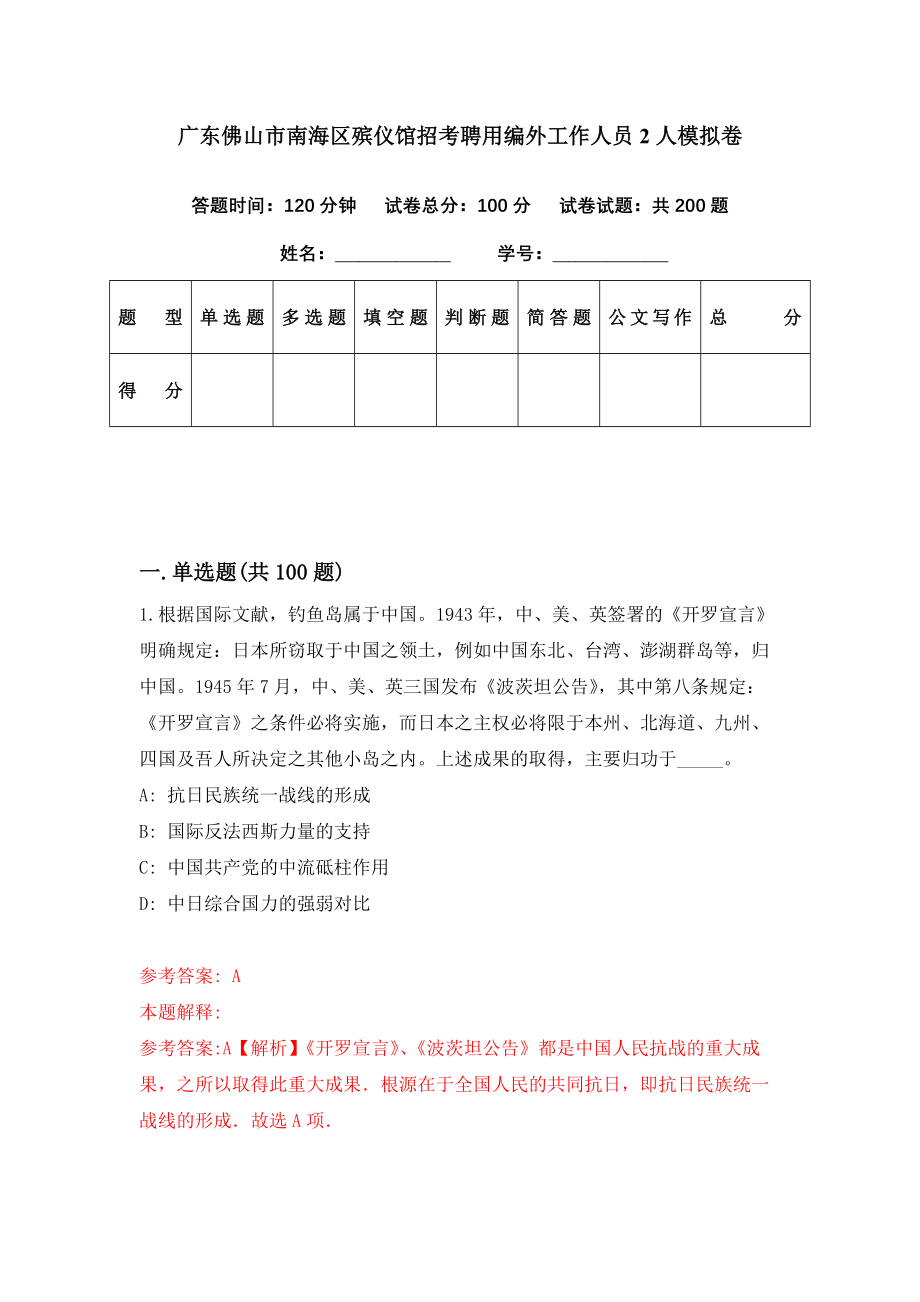

广东佛山市南海区殡仪馆招考聘用编外工作人员2人模拟卷(第82期)

开学第一天日记集锦15篇

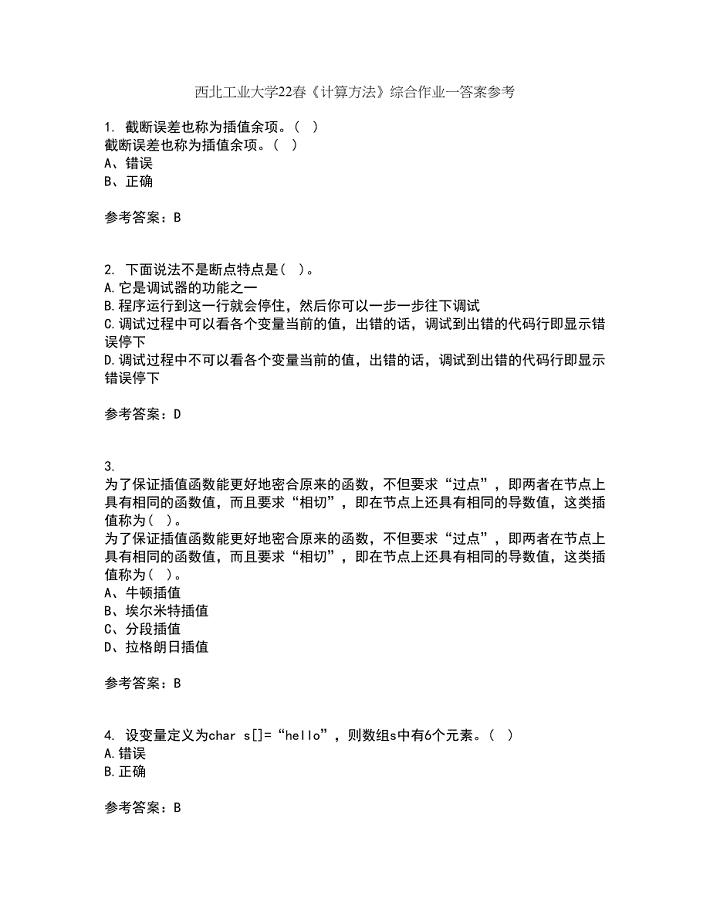

西北工业大学22春《计算方法》综合作业一答案参考12

学习《政府工作报告》心得

高速公路检查通报

公司前台个人工作总结标准样本(2篇).doc

2023学校安全生产月活动总结范本(4篇).doc

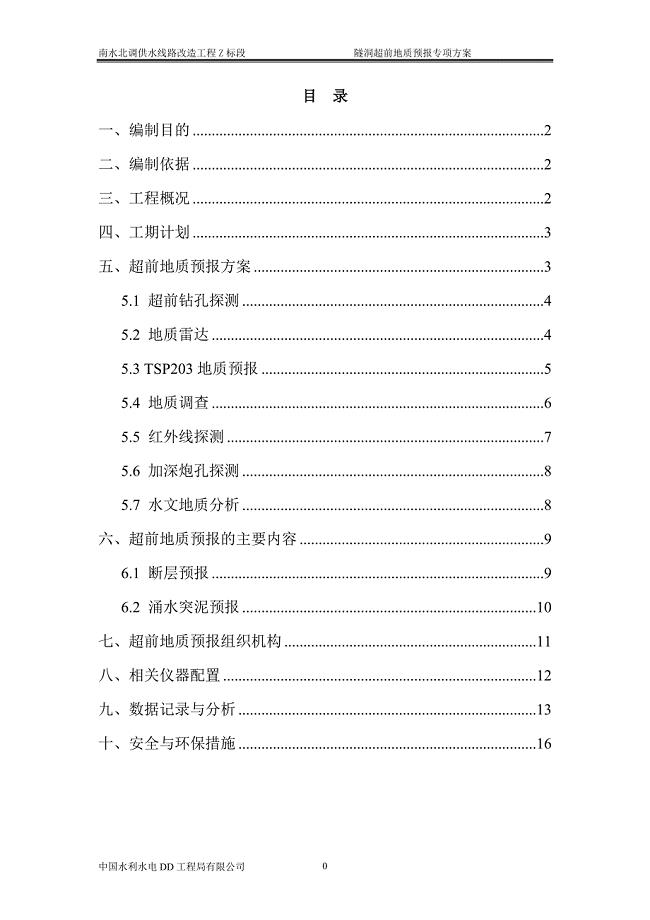

隧洞地质超前预报专项方案

2011一级建造师市政工程真题

精选端午节演讲稿范文锦集八篇

集中来解答一下我的基本面试解题思路

最新《施工组织设计》某楼房钻孔灌注桩工程施工组织设计

审监庭的定位与审监法官的职责

西药学专业知识二考试题库全真模拟试题附答案12

3分钟搞定一种内科疾病:心脏骤停与复苏

感恩母亲演讲稿汇编15篇

投掷轻物评课稿

学案15036

教导处教学工作总结范文.doc

CG2-150型仿型切割机设计说明书

CG2-150型仿型切割机设计说明书

2024-01-04 17页

SF打散分级机总体及机架设计任务书

SF打散分级机总体及机架设计任务书

2022-09-11 5页

PLC控制的节能洗衣机系统设计任务书

PLC控制的节能洗衣机系统设计任务书

2023-09-25 3页

Φ3X11M水泥磨总体设计及传动部件设计任务书

Φ3X11M水泥磨总体设计及传动部件设计任务书

2022-12-14 5页

PLC控制的节能洗衣机系统设计论文

PLC控制的节能洗衣机系统设计论文

2022-08-08 41页

BSG2213宽带砂光机设计毕业论文

BSG2213宽带砂光机设计毕业论文

2022-09-29 40页

FXS80双出风口笼形转子选粉机设计任务书

FXS80双出风口笼形转子选粉机设计任务书

2022-11-08 4页

X502型铣床数控改装设计工作总结

X502型铣床数控改装设计工作总结

2023-10-23 2页

Φ146.6的药瓶及其瓶盖的塑料模具的设计任务书

Φ146.6的药瓶及其瓶盖的塑料模具的设计任务书

2023-08-23 4页

C6140普通车床主轴箱传动设计任务书

C6140普通车床主轴箱传动设计任务书

2022-11-24 2页