Holographic Grating Lithography System (Laser) SOP

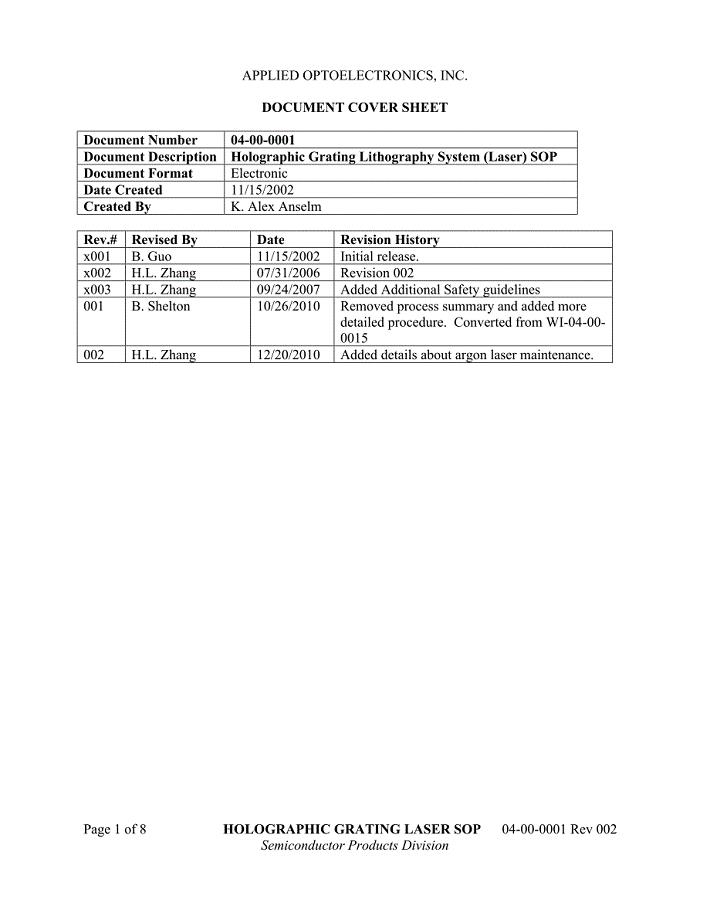

8页1、APPLIED OPTOELECTRONICS, INC.DOCUMENT COVER SHEETDocument Number04-00-0001Document DescriptionHolographic Grating Lithography System (Laser) SOPDocument FormatElectronicDate Created11/15/2002Created ByK. Alex AnselmRev.#Revised ByDateRevision Historyx001B. Guo11/15/2002Initial release.x002H.L. Zhang07/31/2006Revision 002x003H.L. Zhang09/24/2007Added Additional Safety guidelines001B. Shelton10/26/2010Removed process summary and added more detailed procedure. Converted from WI-04-00-0015002H

2、.L. Zhang12/20/2010Added details about argon laser maintenance.Holographic Grating Lithography System (Laser) SOP1) Read and understand all of the laser safety guidelines in Appendix I.a. Turn on the Laser and adjust using the details specified in Appendix II.2) Follow the procedure to prepare the wafer for the exposure process.3) Expose in the holographic system, using the procedure described in Appendix III.4) Argon laser maintenance:Frequencya. Laser optical output power monitoring: Weeklyi.

3、See procedure in Appendix IVb. Laser optical intensity profile measurement: Tube install or after alignment change, and monthly thereafter (after conditioning below).i. Follow procedure in Appendix V.c. Laser tube conditioning: Tube install, monthly thereafter. i. Follow procedure in Appendix VI.Appendix ILaser Safety GuidelinesThe laser used in AOIs grating lithography system is a Spectra Physics BeamLok 2060 Argon gas laser. The maxim rated optical power with the 2060-5S plasma-tube and 363.8n

4、m optics used is 170mW. This laser is a Class IIIB laser. The nominal operation power of the laser during normal operation is 70mW at a UV wavelength of 363.8nm. The radiation of this laser can be dangerous to eyes and skins if exposed. Several safety features and procedures have been built in the grating lithography system to minimize the danger of accidental laser radiation. The laser and the grating holographic lithography optics are enclosed in an enclosure on the optical table. No laser bea

《Holographic Grating Lithography System (Laser) SOP》由会员ovq****plh分享,可在线阅读,更多相关《Holographic Grating Lithography System (Laser) SOP》请在金锄头文库上搜索。

中国移动集团认证考试L1动力系统选择题库

中国移动集团认证考试L1动力系统选择题库

2021-12-08 72页

通信专业技术人员初级、中级职业水平考试-通信专业综合能力(中级-答案)

通信专业技术人员初级、中级职业水平考试-通信专业综合能力(中级-答案)

2021-12-07 7页

通信专业技术人员初级、中级职业水平考试-通信专业综合能力小条

通信专业技术人员初级、中级职业水平考试-通信专业综合能力小条

2021-12-07 2页

通信专业技术人员初级、中级职业水平考试-通信专业实务(传输与接入)(精校)

通信专业技术人员初级、中级职业水平考试-通信专业实务(传输与接入)(精校)

2021-12-07 7页

通信专业技术人员初级、中级职业水平考试-最新通信专业实务传输与接入(中级)

通信专业技术人员初级、中级职业水平考试-最新通信专业实务传输与接入(中级)

2021-12-07 11页

通信专业技术人员初级、中级职业水平考试通信专业综合能力中级-答案

通信专业技术人员初级、中级职业水平考试通信专业综合能力中级-答案

2021-12-07 9页

429板卡 GE反射内存卡

429板卡 GE反射内存卡

2021-10-04 3页

1553b航电总线

1553b航电总线

2021-10-04 2页

建设工程工地现场恶劣天气专项应急预案异常高温及防止人员中暑应急预案

建设工程工地现场恶劣天气专项应急预案异常高温及防止人员中暑应急预案

2020-05-21 8页

建设工程工地现场环境污染事件专项应急预案

建设工程工地现场环境污染事件专项应急预案

2020-05-21 14页