无损检测翻译外文原文及翻译

3页1、1.Key Techniques of the X-ray Inspection Real-time Imaging Pipeline Robot This paper presents a robotic system for weld-joint inspection of the big-caliber control ofsyncbro-follow control technique it can accomplish the technologic task of weld inspection. Therobotic system is equipped with a small focal spot and directional beam X-ray tube so the higherdefinition image of weld-seam can be obtained.Several key techniques about the robotic systemdeveloped are also explained in detail . Its const

2、ruction is outlined.Key words : X-ray inspection:real-time imagingrobotIntroduction Compared with radiographic examination teohniqueRETX-ray real time imaginginspection techniqueRTIIT has many advantages such as higher efficiency lower cost betterfeasible automation and weld-defects evaluation on-line.Furthermore,up to date technologyallows the X-ray RTIIT to be used in Non-Destructive Testing NDT of pipelines,and theinspection quality of this Technique is as good as that of the RET. Therefore N

3、DT equipments,which are used commonly in pipeline inspection and basing on the RET,need to be renovated bybasing on the X-ray RTIIT. To employ the X-ray RTITT in NDT of pipeline there must be an automation platform,andX-ray inspection real-time imaging pipeline robotIRTIPR is designed for the purpose. In factbesides the problems that have been resolved and are involved in the X-ray IRTIPRseveral keytechniques are presented in this paperin which we address the robot focusing on its intelligentcon

4、trol such as the autonomous motion in-pipe,the synchro-follow controltechnique and thecommunication of cooperation between in-pipe and out-pipe and we also outline the constructionof the robot.1 Composing and Working Principle of the Robot The X -ray IRTIPR connints of the two parts of in-pipe and out-pipe,as illustrated in Figl1 .The out-pipe part is camposed of mage collecting and processing system , out-pipesynchro-rotary mechanism and its driving system.The image intensifier is driven by the

5、 out-piperotary mechanism to rotate round the center of pipeline to collect weld image and transmit videosignal to image processing computer image-collecting card. The in-pipe part is composed ofin-pipe computer,power and invcrters system ,walking and driving system ,X-ray system,in-pipe synchro-rotary rncchanism and its driving system and weld 一 seam autonomous seekingand locating system .TheX -ray tube in x-ray system is driven by the in-pipe rotary mechanism torotate round the center of pipel

《无损检测翻译外文原文及翻译》由会员汽***分享,可在线阅读,更多相关《无损检测翻译外文原文及翻译》请在金锄头文库上搜索。

高年级语文教研组工作计划.docx

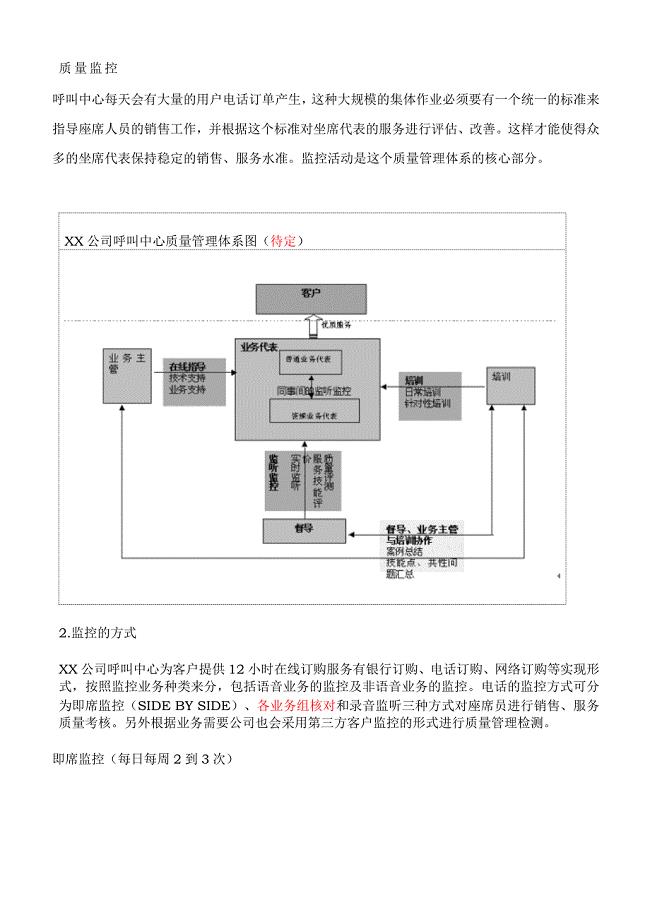

CC质检培训流程讲解

有关年级班主任年度工作总结5篇.doc

历年高考真题之-欧洲(含俄罗斯).doc

(完整word版)2018年高考英语(全国I卷)试题及参考答案(word版)(2)

林业专业大学入学教育心得体会.docx

后发性白内障有哪些表现.doc

房屋按揭贷款购买合同样本3篇-《购房按揭合同》.docx

声现象--超声波和次声波---第三章第三节.doc

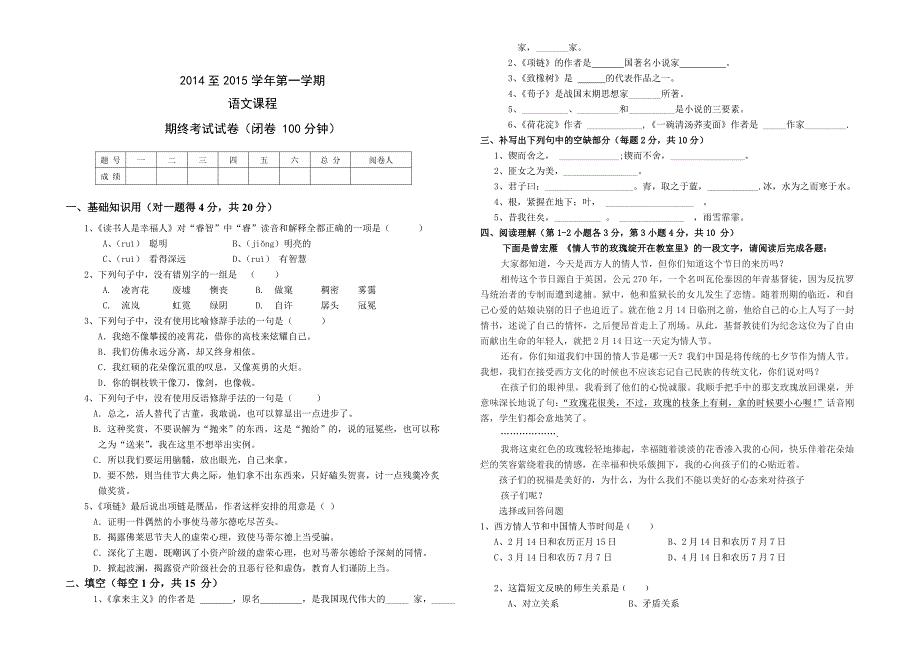

中职语文基础模块上册期末试题

![[精选]大学800字军训心得体会 .doc](https://union.152files.goldhoe.com/2023-4/13/eea6e6d1-35a4-426c-bb96-6db3a76973ff/pic1.jpg)

[精选]大学800字军训心得体会 .doc

![感谢党的恩情演讲稿多篇[共5页]](https://union.152files.goldhoe.com/2024-1/18/3d27df7a-a4a0-48a2-bf53-4e88598ac949/pic1.jpg)

感谢党的恩情演讲稿多篇[共5页]

第四组单元分析及单元试题.doc

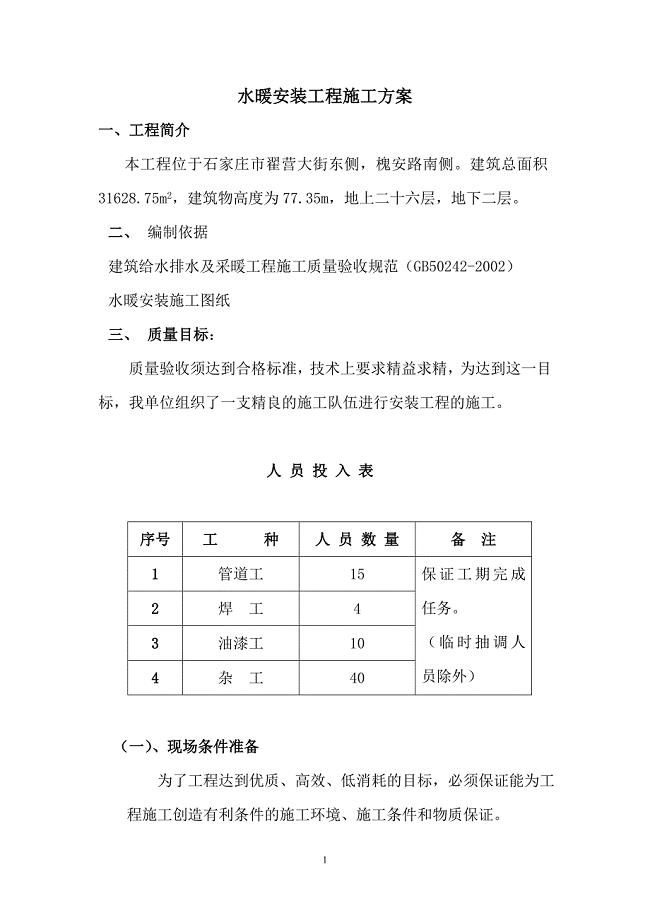

87438安装工程施工方案

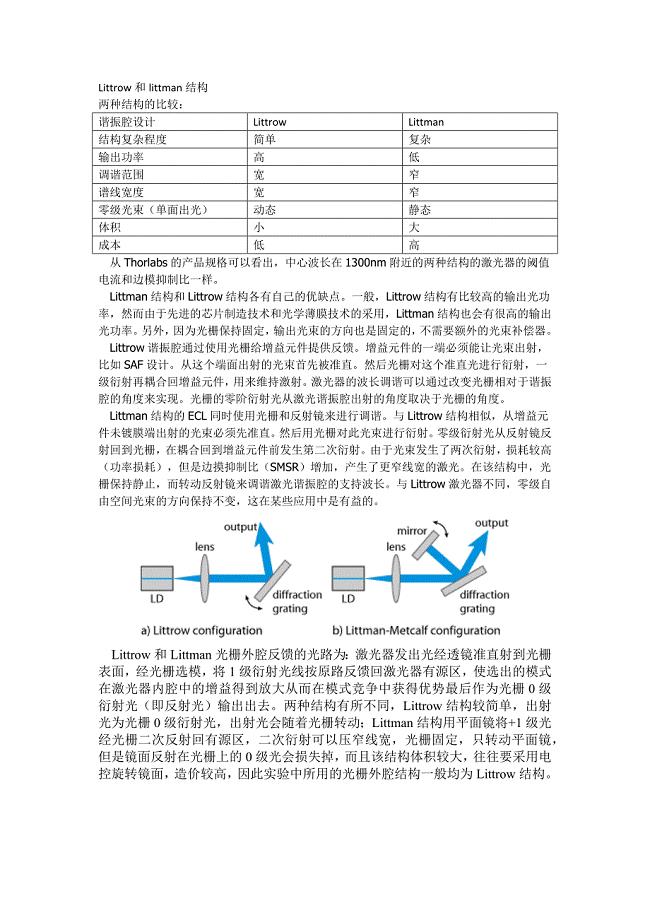

littrow和littman结构.docx

焦作航空材料研发项目可行性研究报告_模板参考

【“水井坊”范本】 水井坊酒价格表.docx

音乐教学中如何培养学生的学习兴趣.doc

如何实现教育教学改革与实践

六年级奥数题及答案(全面).doc

房地产竣工验收全过程(l理论实践版)

房地产竣工验收全过程(l理论实践版)

2023-03-27 4页

部编版五年级道德与法治下册教学计划

部编版五年级道德与法治下册教学计划

2023-03-21 3页

陕西省普通高中学业水平考试化学试题真题

陕西省普通高中学业水平考试化学试题真题

2023-08-21 12页

房地产项目建议

房地产项目建议

2023-03-09 28页

《工业废水处理氧化塘工程施工组织设计》

《工业废水处理氧化塘工程施工组织设计》

2023-02-19 45页

环氧树脂地坪施工及养护方法

环氧树脂地坪施工及养护方法

2023-09-29 6页

大气三层复式客厅别墅设计图纸及效果图

大气三层复式客厅别墅设计图纸及效果图

2024-02-18 2页

工程投标与工程利润预算

工程投标与工程利润预算

2023-09-08 2页

《工程经济学》期末综合测试

《工程经济学》期末综合测试

2022-09-15 8页

粉喷桩处理软基设计方法及施工质量管理

粉喷桩处理软基设计方法及施工质量管理

2023-04-27 4页