外文翻译--基于DSP技术为机车轴承设计故障诊断监控系统.doc

10页1、Design of Fault Diagnosis Monitor System for the Locomotive Bearings Based on DSP TechnologyAbstractThe rolling bearing is one of the key parts of the locomotive running components, because it condition is directly related to the performance and safety of locomotive. In this paper, the monitor system for the locomotive bearings based on DSP TMS320LF2407A is designed. This system diagnoses the rolling bearing fault using vibration analysis method. It is based on comprehensive resonance demodulati

2、on and fast Fourier transform technique, and it adopts related methods to handle the result of the FFT. It effectively improves the response characteristics, sensitivity, differentiate and measurement accuracy of the bearing failure monitor system, and it can fulfill the monitor and prediction of the transient fault in the course of the locomotive running.Key words: resonance demodulation technology; digital signal processor; related methods I. IntroductionThe higher safety is required to the tr

3、ains because its speed is raised constantly. Bearing fault is one of the major factors causing eventful traffic accidents and affecting rail safety. Currently the railway system usually uses the bearing temperature detector to monitor the locomotive bearing condition. Theoretical analysis and a lot of practice show that the bearing temperature detector can prevent accidents from occurring to some extent, but most of the bearing fault is not sensitive to temperature. When the temperature of the b

4、earing is beyond the range and the system gives an alarm, the worse damage of the bearing has occurred, and even the incident had happened. Therefore, to find the fault more early and accurately, the more advanced monitoring means must be adopted. Most of the bearing fault is very sensitive to vibration signal. The fault can cause vibration of the bearing increased. Compared with monitoring the temperature of bearing, the analysis and processing results to the vibration signal has more advantage

《外文翻译--基于DSP技术为机车轴承设计故障诊断监控系统.doc》由会员cl****1分享,可在线阅读,更多相关《外文翻译--基于DSP技术为机车轴承设计故障诊断监控系统.doc》请在金锄头文库上搜索。

2022年会计证财经法规职业道德内容详解(4).docx

司蕨麻猪养殖扩建项目建设可行性研究报告.doc

停车场经营管理系统方案设计66063

关于民族精神的演讲稿

2023年孩子成长寄语美好句子与学生一起快乐成长.docx

试卷保密承诺书

2023年酒店考察学习心得体会范文.docx

绿化承包合同参考范本(5篇).doc

用自己的爱心营造一片阳光.doc

混合运算教学设计.docx

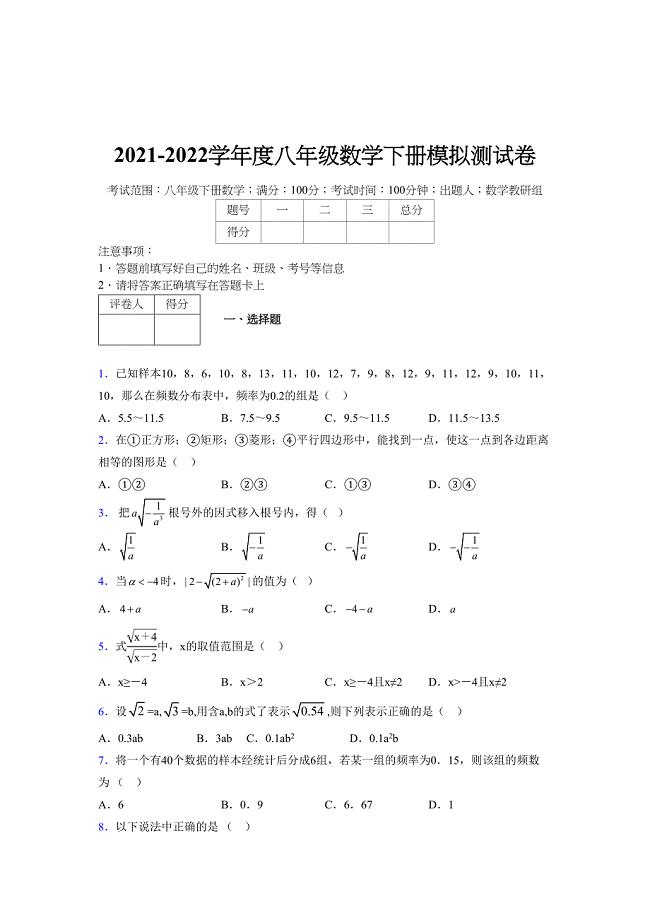

2021-2022学年度八年级数学下册模拟测试卷-(1099).docx

常见疾病反应点.doc

ui自我介绍500字.docx

2023年公司青年文明岗申报.doc

2023大学生村官年终个人考核总结范文

村委会选举选票

XX煤矿动力科各项规章制度汇编

新人教版五年级数学上册全单元测试题(免费).docx

六一表彰决定.doc

2023教案人教版小学六年级《藏戏》课文内容.docx

订餐服务合同模板(4篇).doc

订餐服务合同模板(4篇).doc

2023-05-12 8页

办公室租赁安全协议书范本(五篇).doc

办公室租赁安全协议书范本(五篇).doc

2022-10-20 18页

涂装车间安全管理规定

涂装车间安全管理规定

2022-08-11 3页

电脑采购合同格式版(七篇).doc

电脑采购合同格式版(七篇).doc

2022-08-06 16页

财务保密协议样本(10篇).doc

财务保密协议样本(10篇).doc

2024-02-04 53页

厂房租赁安全协议书简易参考样本(3篇).doc

厂房租赁安全协议书简易参考样本(3篇).doc

2022-11-06 6页

夫妻房产赠与协议格式版(二篇).doc

夫妻房产赠与协议格式版(二篇).doc

2023-02-25 3页

两人餐饮合作协议书常用版(3篇).doc

两人餐饮合作协议书常用版(3篇).doc

2023-05-02 6页

铺面出租合同下载范本

铺面出租合同下载范本

2023-06-15 2页

门面转让协议格式版(2篇).doc

门面转让协议格式版(2篇).doc

2023-10-03 5页