美国四分制和十分制中英文

19页1、美國四分制和十分制Fabric Inspection System.Fabric inspection and QC is one of the major areas in textile and garment sector. To establish a workable system for inspecting and evaluating piece goods shipments is vital. No single accepted system for measuring the quality of fabrics, but some of the more commonly used systems are described in this section.We recommend a minimum of 10% inspection of fabrics prior to spreading. Some are intending to inspect the goods while spreading. However this is unrealist

2、ic and the spreaders are not the QC.1-Ten-Point SystemIn 1955, the Ten-Point System for piece goods evaluation was approved and adopted by the Textile Distributors Institute and National Federation of Textiles. This system assigns penalty points to each defect, depending on its length. The Ten-Point System is somewhat complicated because points-per-length vary for warp and filling defects. Table blow shows a breakdown of the points:Table 1 - Ten-Point SystemWarp Defects Penalty Filling Defects P

3、enalty10-36 inches 10 points Full width 10 points5-10 inches 5 points 5 inches - 1/2 the width of goods 5 points1-5 inches 3 points 1-5 inches 3 pointsUp to 1 inch 1 pointUnder the Ten-Point System, a piece is graded a first if the total penalty points do not exceed the total yardage of the piece. A piece is graded a second if the total penalty points exceed the total yardage of the piece.2- Four-Point SystemThe Four-Point System has received the widest acceptance in both the textile and needle

4、trades because it is the most lenient. It is simple and easy to understand. Since it is the most widely used?2.1- Amount to Inspect - Inspect at least 10% of the total rolls in the shipment.2.2- Selection of Rolls Select at least one roll of each color. If more than one roll per color must be inspected, then select the number of additional rolls in proportion to the total rolls per color received.2-3 Defect Classification The Four-Point System classifies defects as shown in Table 2:Table 2 Four-

《美国四分制和十分制中英文》由会员m****分享,可在线阅读,更多相关《美国四分制和十分制中英文》请在金锄头文库上搜索。

助理工程师的工作总结.docx

全胃肠外营养并发症的预防及护理.docx

龙江县金帝雅阁一期棚户区开发项目策划书.doc

第4课 欧洲启蒙思想(教学设计).doc

实习班主任个人工作总结范文2

公交智能收费系统的设计说明

让爱的教育绽放美丽.doc

无人机AOPA多旋翼地面站考试考点攻略201808.docx

正方体的截面有哪些形状.docx

清代犯屯的一个另类.doc

普通话学习心得体会.docx

建德市关于成立中医公司可行性分析报告

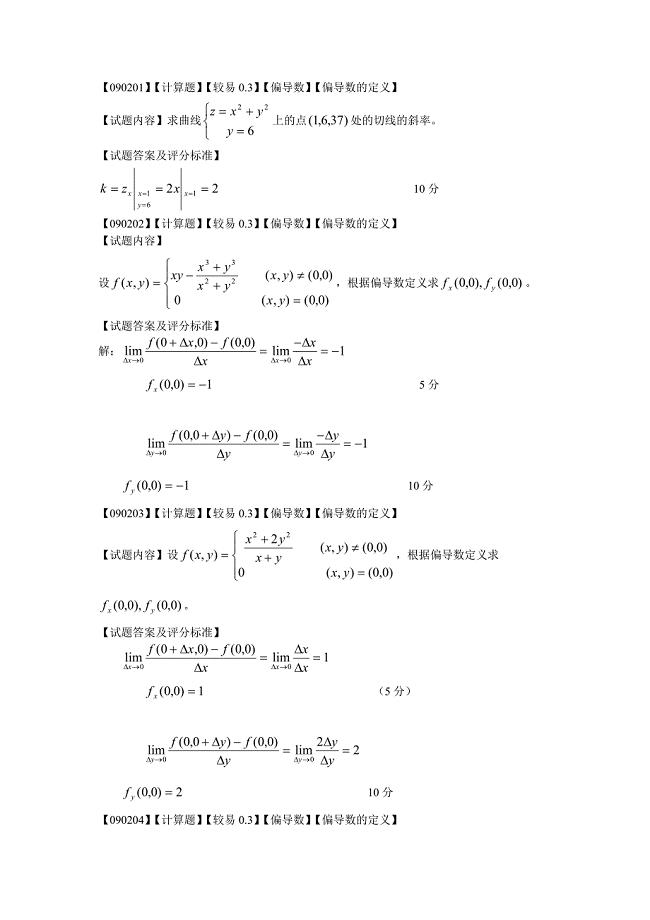

高等数学偏导数第二节题库

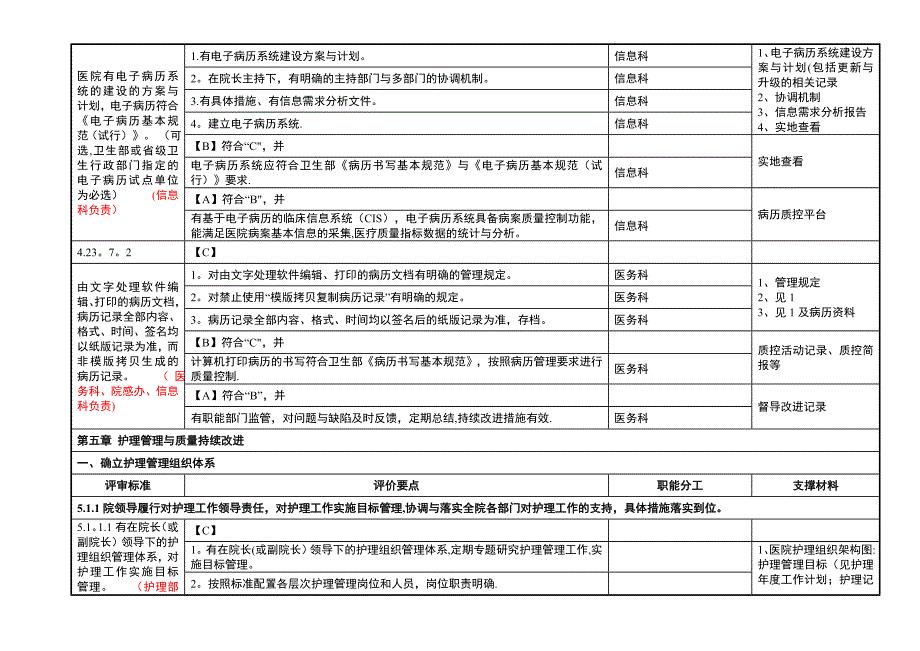

医院有电子病历系统的建设的方案与计划.doc

教你手机维修入门知识

2023年医院内部审计工作计划3范文.docx

有固定期限劳动关系终止协议样本(9篇)

(完整word版)高考语文标点符号使用详解.doc

4第四章 资本主义的形成及其本质10263.doc

高处作业的安全技术措施及其所需料具

如何从外形辨认好水果.doc

如何从外形辨认好水果.doc

2023-04-23 6页

皮炎的临床分类症状是什么.doc

皮炎的临床分类症状是什么.doc

2023-08-21 3页

木龙骨吊顶施工工艺标准

木龙骨吊顶施工工艺标准

2022-10-25 16页

单方白术巧治便秘.doc

单方白术巧治便秘.doc

2023-03-01 10页

趣味性实验11-1.doc

趣味性实验11-1.doc

2023-03-13 5页

心脏瓣膜病的病理生理与诊断

心脏瓣膜病的病理生理与诊断

2023-08-13 19页

精品高考地理二轮小题提速练:9 Word版含解析

精品高考地理二轮小题提速练:9 Word版含解析

2024-01-09 4页

实验讲义-音叉实验-2012.doc

实验讲义-音叉实验-2012.doc

2023-01-21 7页

胎心监护操作考核评分标准图文

胎心监护操作考核评分标准图文

2022-11-30 4页

公交智能收费系统的设计说明

公交智能收费系统的设计说明

2023-10-28 74页