外文翻译--压力机.doc

14页1、附录英文翻译Lever body is a 500 t, 600 t, 800 t, 1300 t, 2000 t mechanical press on an important component mold clamping body parts, is the companys key project trial. Currently, foreign-made lever body is formed in the die forging hammer, forging internal quality and appearance than those of good quality. Forging abroad as domestic manufacturers do not have the condition, only in the free forging hammer on the shape, quality is hard to meet the design requirements. As the lever body parts surface mor

2、e, if completely rely on forming, not only difficult process, and present material waste, processing cycles, high costs; In addition, as lever shaped body of work load is large, the mechanical performance requirements of materials higher. The process forming the lever body, the Central Department of fiber unreasonably difficult to guarantee quality of the work lever body. Thus, according to technical conditions existing programs to determine forging manufacturing with membranes and to identify w

3、ith the local combination of forging and free forging methods.Using such a forging process has the following advantages:(1) leverage with the local body after the ring Die Department of fibers reasonable to ensure the quality forgings;(2), compared with the overall forging, die length, 1.9 times shorter, the module small size, low cost; (3) can gain leverage in the 400 kg pneumatic hammer directly on the molding, to improve efficiency. In contrast, the overall die forging hammer blow in the 400

4、kg pre-forging, pneumatic hammer, shaping the 3t, modules large high labor intensity, low efficiency; (4) plus the free use of local Forging Process, production preparation period is short, can quickly form a production capacity;(5) reduced cold difficulty, shortened processing cycles, saving processing costs. Therefore, the use of local plus free forging die forging process scheme can only guarantee the quality forgings, while head of production efficiency, and cost advantages. But the material

《外文翻译--压力机.doc》由会员汽***分享,可在线阅读,更多相关《外文翻译--压力机.doc》请在金锄头文库上搜索。

2023运营工作计划(二篇).doc

松鼠ppt.doc

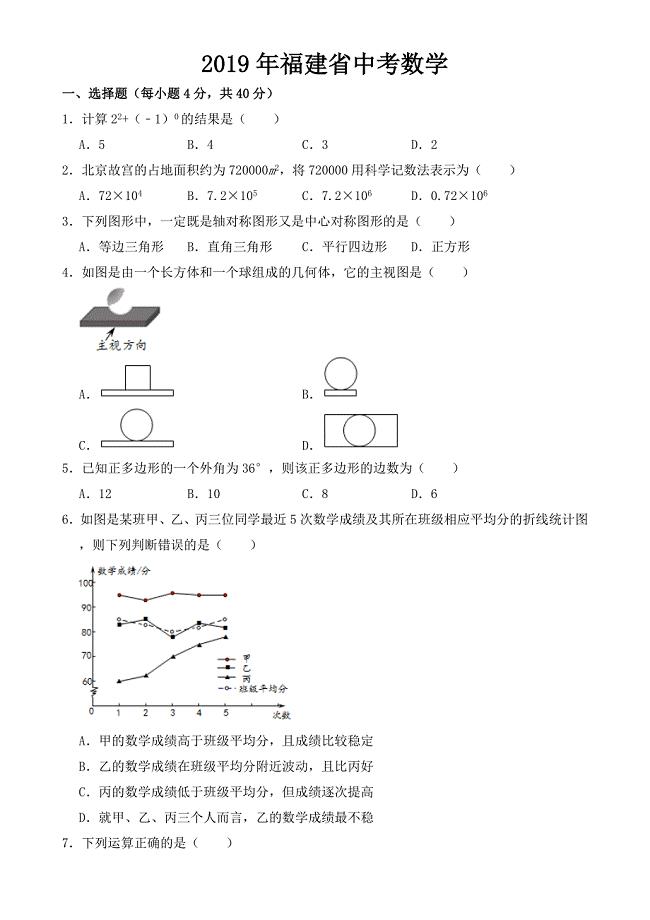

福建省2019年中考数学试题【含答案】.doc

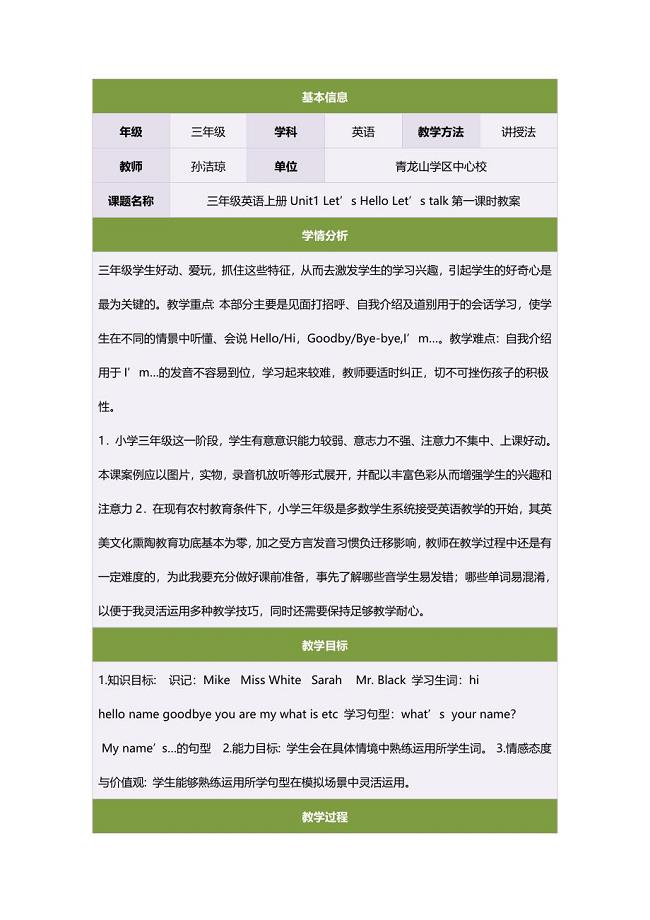

英语上册教案.doc

三国鼎立作业

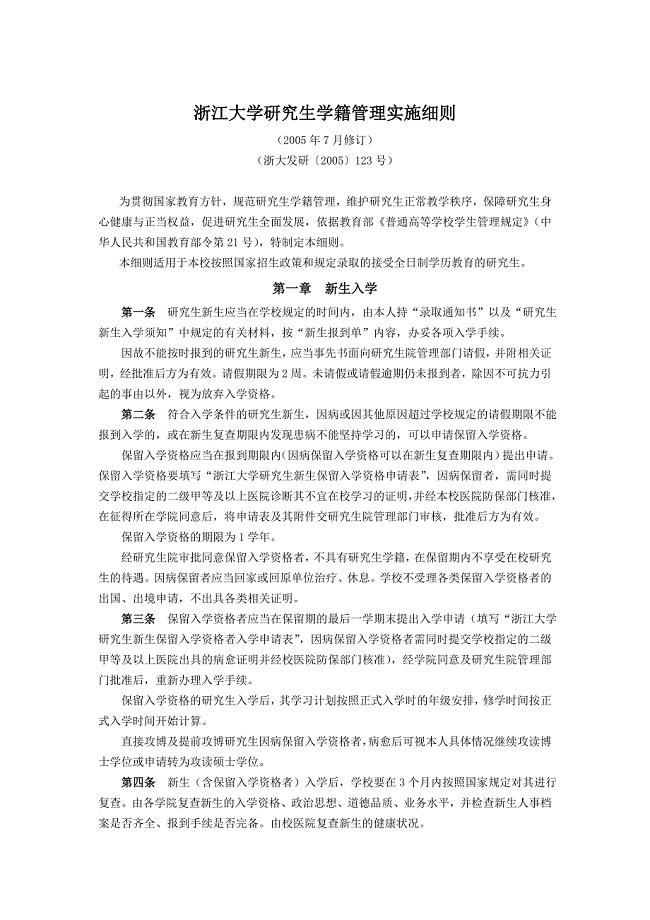

浙江大学研究生学籍管理实施细则

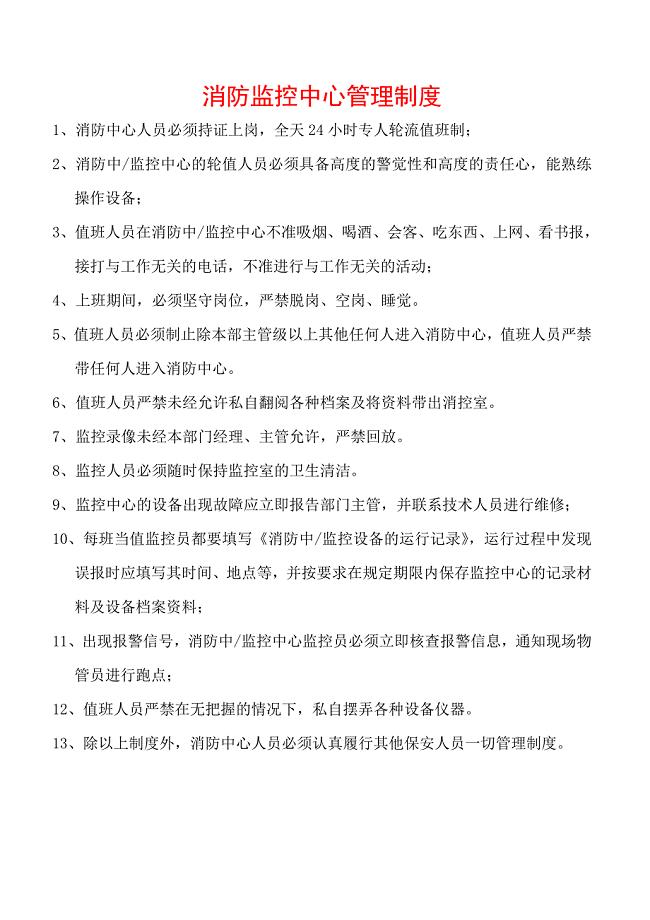

消控室制度(最新).doc

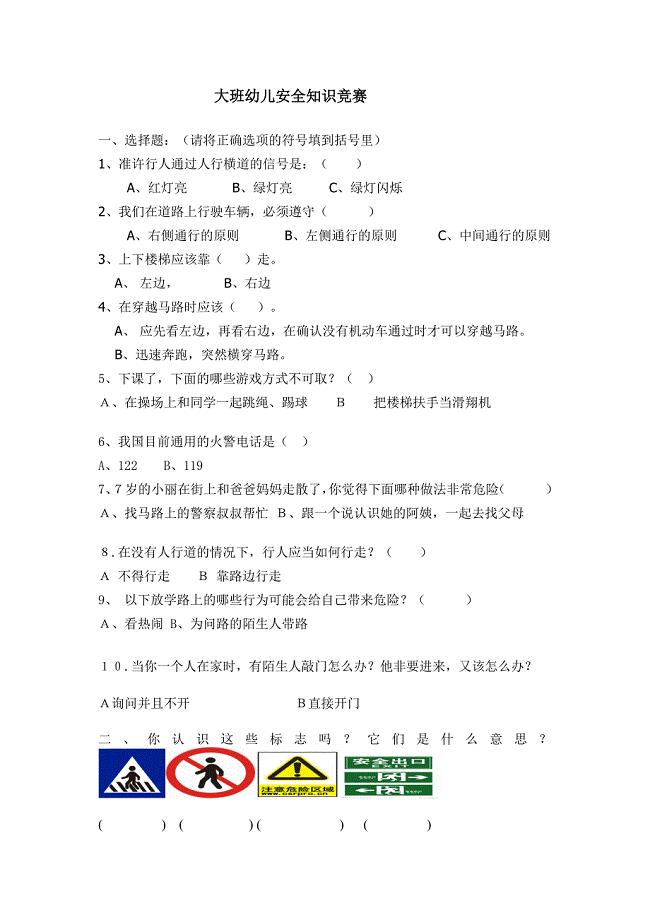

安全知识竞赛题.doc

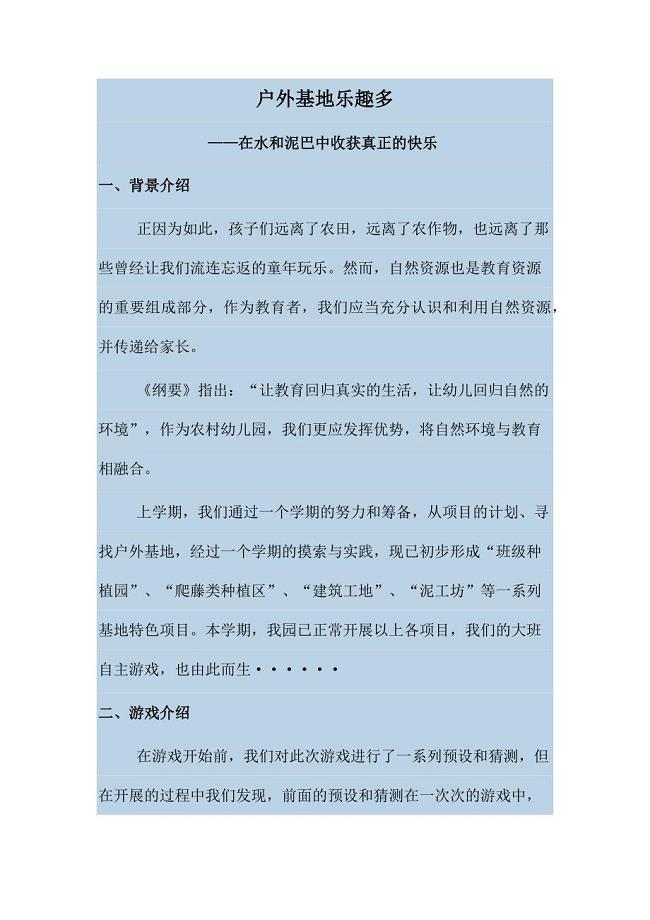

游戏的重要性.docx

《第3节 原子结构的模型》教案1.doc

第十课我设计的一本书教案.doc

2023年小学班级安全工作总结.docx

学习《对于制定国民经济和社会发展第十四个五年规划建议》开展绿色生活创建活动心得体会.docx

大班中国画教案:猴趣.doc

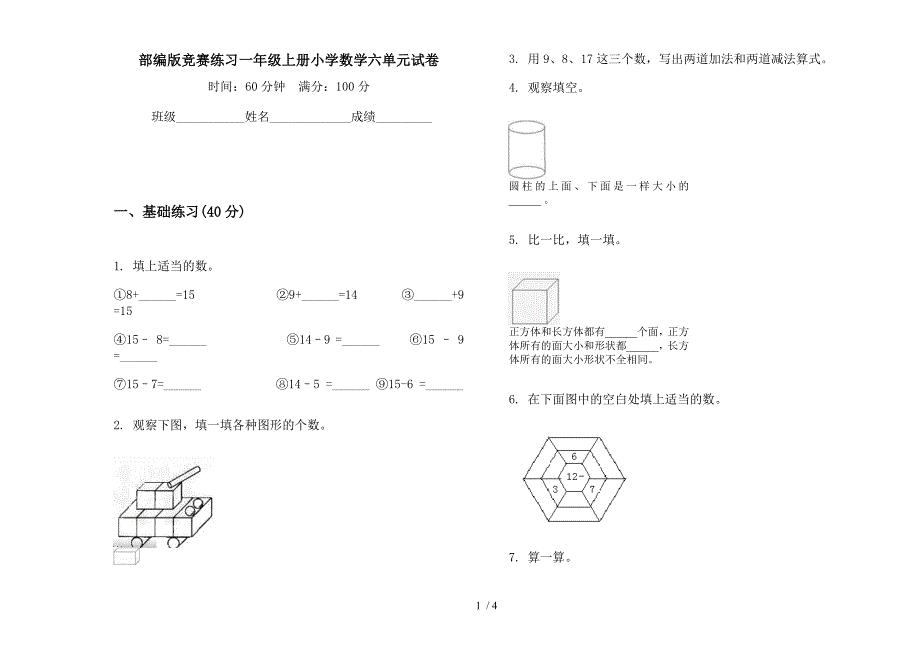

部编版竞赛练习一年级上册小学数学六单元试卷.docx

2023年5月家长会学生代表发言稿范文.docx

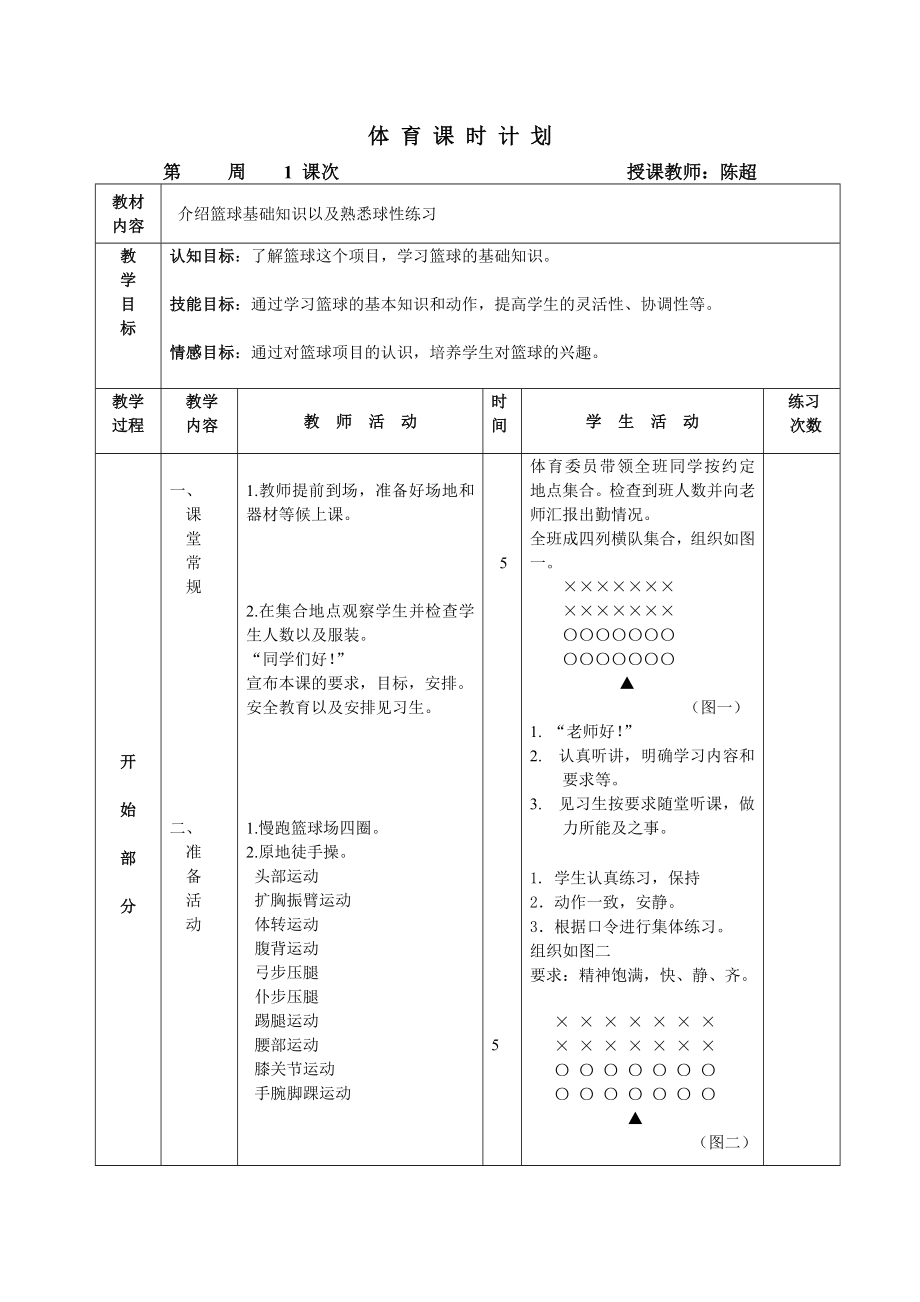

初中篮球课时教案.doc

初精选地理教师上学期工作总结(优选).doc

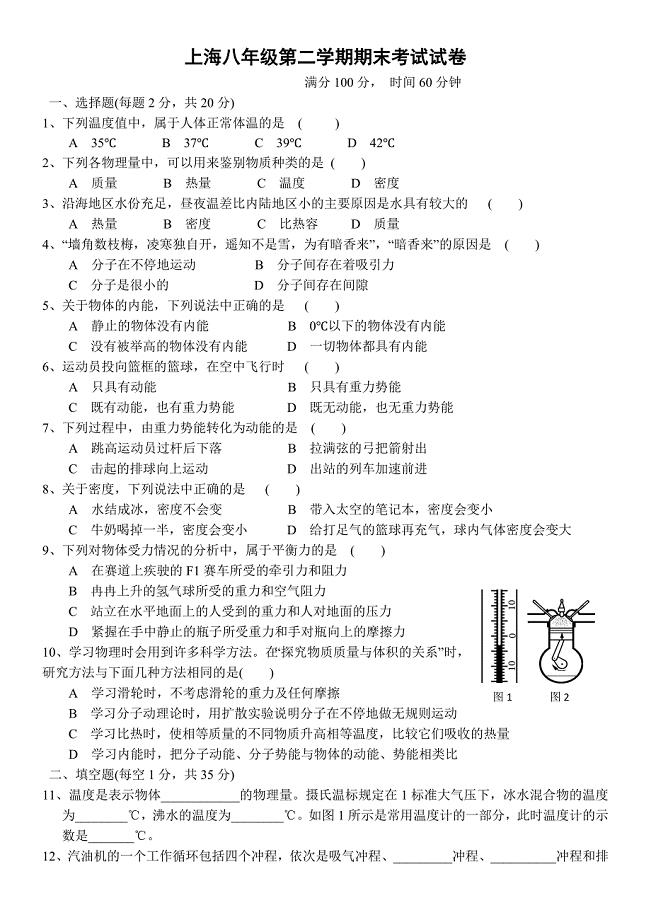

上海物理八年级第二学期期末考试试卷含答案

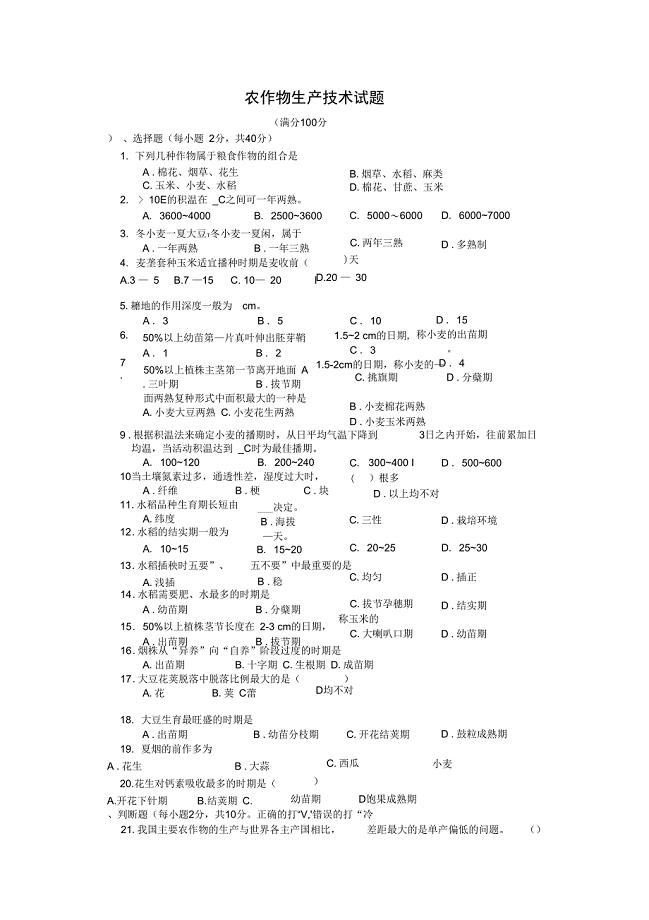

2009年作栽试题(精)

果蔬加工项目商业计划书写作模板

果蔬加工项目商业计划书写作模板

2023-11-18 40页

高精度电梯导轨全流程项目商业计划书写作模板

高精度电梯导轨全流程项目商业计划书写作模板

2022-09-25 41页

关于聘任学生家长为学校义务安全监督员的决议.doc

关于聘任学生家长为学校义务安全监督员的决议.doc

2022-09-26 3页

金属支架展示架项目建议书写作模板

金属支架展示架项目建议书写作模板

2023-01-26 63页

溴化镧晶体及探测器项目商业计划书写作模板

溴化镧晶体及探测器项目商业计划书写作模板

2023-02-18 41页

磷酸盐前驱体材料建设项目可行性研究报告-可修改模板案例

磷酸盐前驱体材料建设项目可行性研究报告-可修改模板案例

2023-01-20 112页

50万吨聚乙醇酸(PGA)生物可降解材料项目建议书写作模板-定制

50万吨聚乙醇酸(PGA)生物可降解材料项目建议书写作模板-定制

2024-03-01 65页

脱氧剂项目商业计划书写作模板

脱氧剂项目商业计划书写作模板

2023-05-18 40页

10万台套高附价值电动汽车充电逆变动力总成智能化技改项目建议书写作模板-定制

10万台套高附价值电动汽车充电逆变动力总成智能化技改项目建议书写作模板-定制

2023-03-07 66页

制备硫酸镍钴锰和电池级碳酸锂项目商业计划书写作模板

制备硫酸镍钴锰和电池级碳酸锂项目商业计划书写作模板

2023-05-03 42页