外文翻译--液压管路和管接头.doc

25页1、徐州工程学院毕业设计附录附录一英文原文Hydraulic Conductors and FittingsEric Sandgren *, T.M. Cameronto account for uncertainty aMechanical Engineering, Virginia Commonwealth University, 601 West Main Street, P .O. Box843015, Richmond, VA 23284-3015, USA Received 19 October 2001;accepted 5 June 20021.1 INTRODUCTIONIn a hydraulic system, the fluid flows through a distribution system consisting of conductors and fittings, which carry the fluid from the reservoir through operating components and back to the reservoir.

2、 Since power is transmitted throughout the system by means of these conducting lines (conductors and fittings used to connect system components), it follows that they must be properly designed in order for the total system to function properly.Hydraulic systems use primarily four types of conductors:1.Steel pipes2.Steel tubing3.Plastic tubing4.Flexible hosesThe choice of which type of conductor to use depends primarily on the systems operating pressures and flow rates. In addition, the selection

3、 depends on environmental conditions such as the type of fluid, operating temperatures, vibration, and whether or not there is relative motion between connected components.Conducting lines are available for handling work pressures up to 10,000 Pa or greater. In general, steel tubing provides greater plumbing flexibility and neater appearance and requires fewer fittings than piping. However, piping is less expensive than steel tubing. Plastic tubing is finding increased industrial usage because i

4、t is not costly and circuits can be very easily hooked up due to its flexibility. Flexible hoses are used primarily to connect components that experience relative motion. They are made from a large number of elastomeric (rubberlike) compounds and are capable of handling pressures exceeding 10,000 Pa.Stainless steel conductors and fittings are used if extremely corrosive environments are expected. However, they are very expensive and should be used only if necessary. Copper conductors should not

《外文翻译--液压管路和管接头.doc》由会员工****分享,可在线阅读,更多相关《外文翻译--液压管路和管接头.doc》请在金锄头文库上搜索。

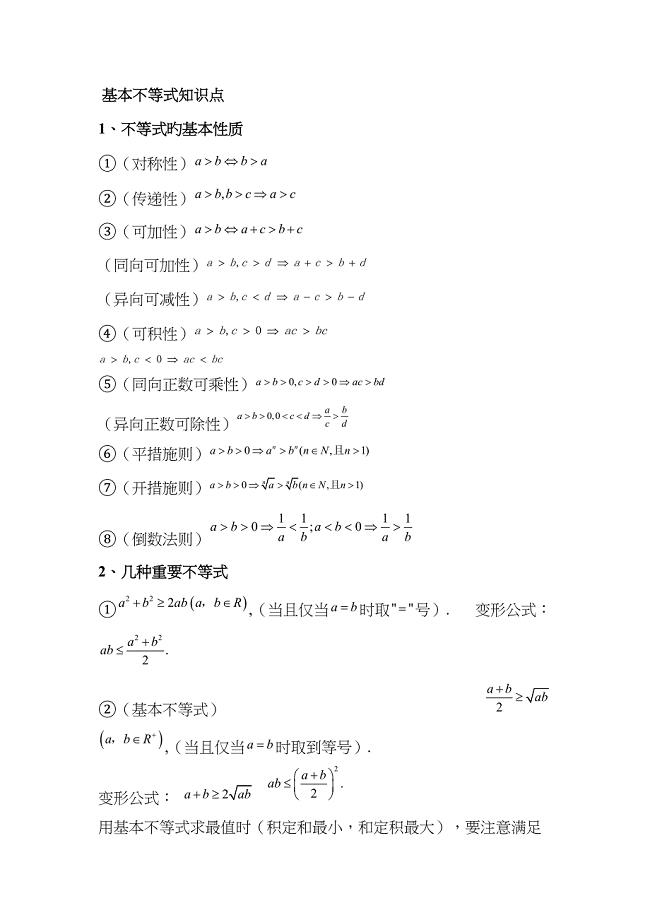

2022年基本不等式知识点.doc

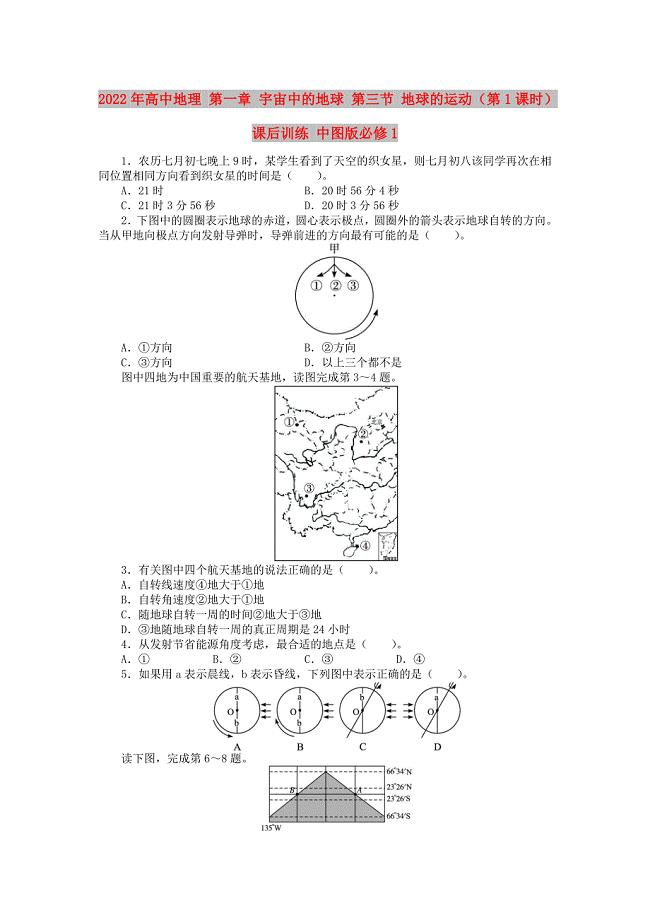

2022年高中地理 第一章 宇宙中的地球 第三节 地球的运动(第1课时)课后训练 中图版必修1

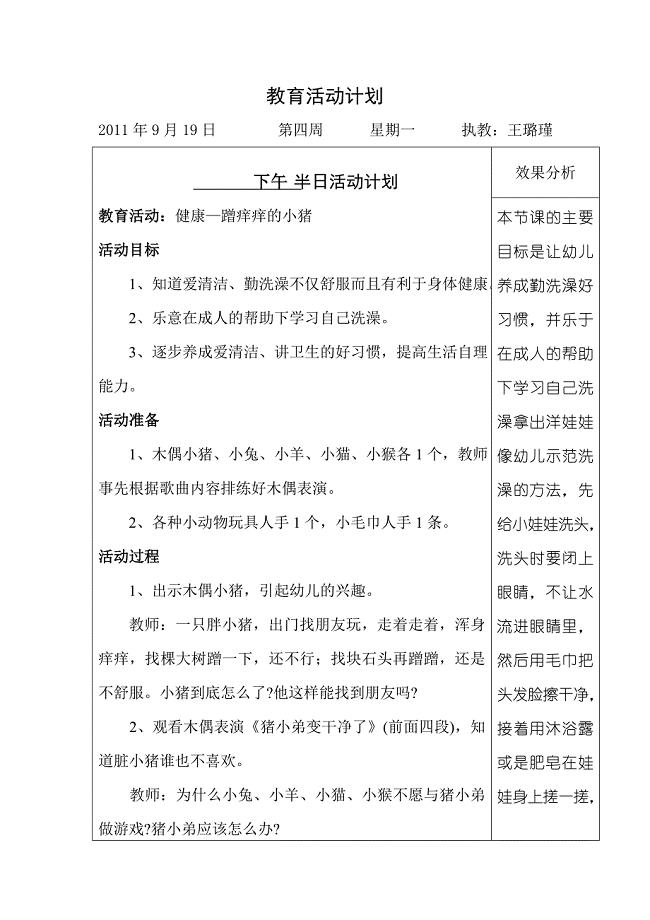

健康—蹭痒痒的小猪.doc

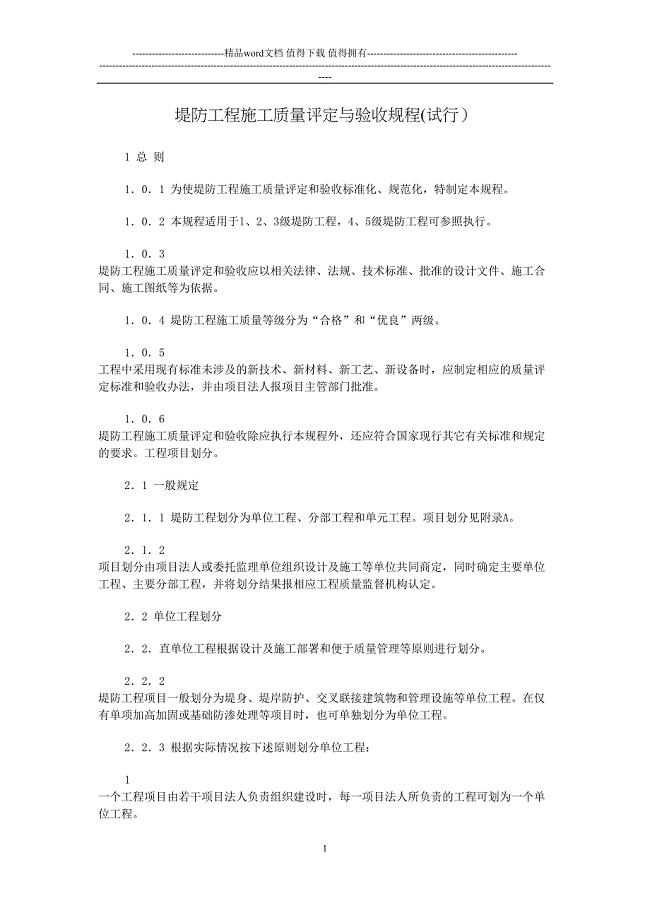

堤防工程施工质量评定与验收规程(试行)(DOC 33页)

疾病调查报告4篇

啤酒废水处理厂沼气发电与余热利用

5万套瓷酒瓶项目可行性报告

2022年土建工程师个人工作总结范文

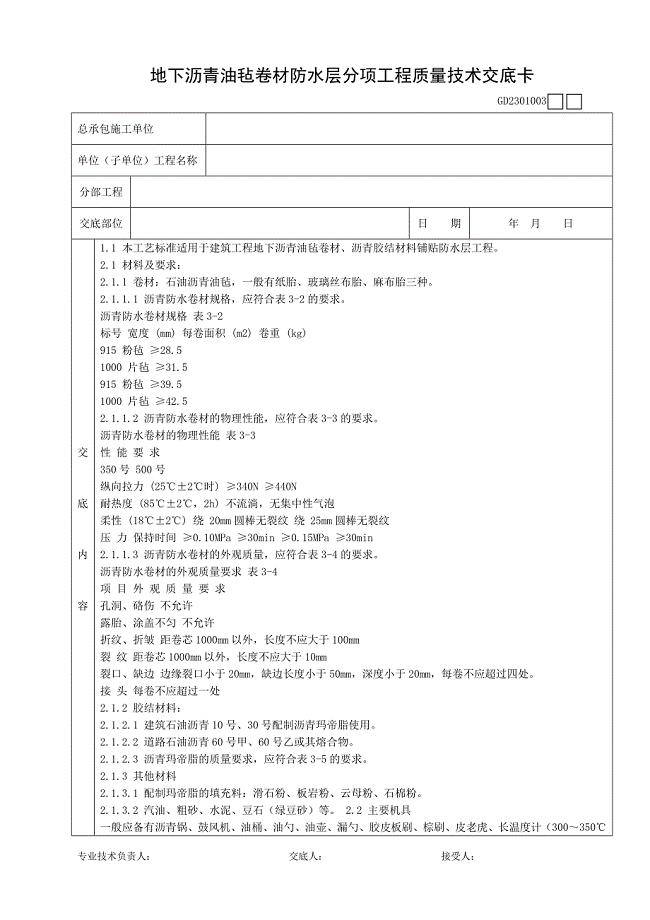

【最新资料】地下沥青油毡卷材防水层分项工程质量技术交底卡

文明施工承诺书汇总10篇

三好学生演讲稿四篇

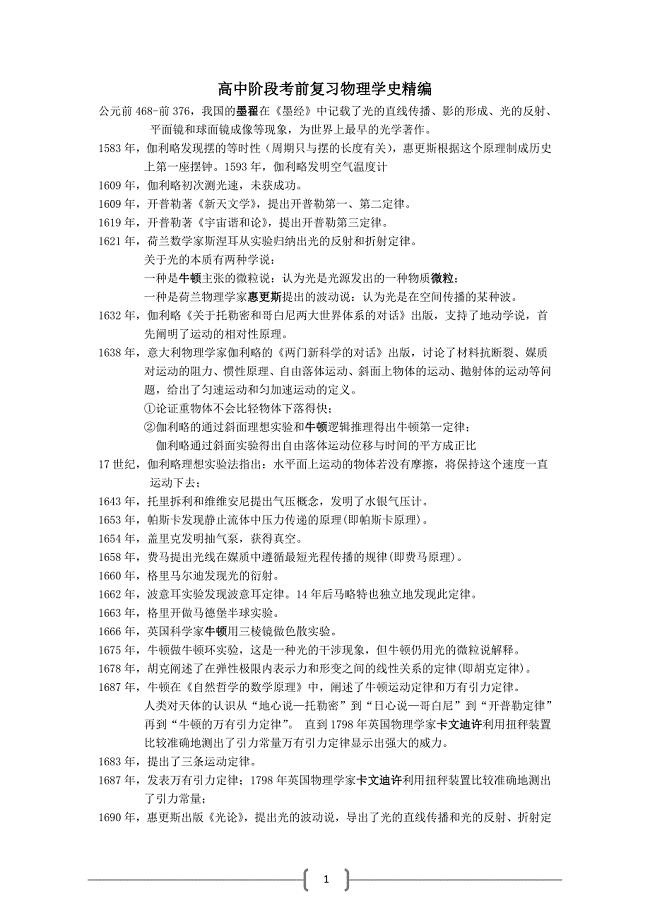

高中阶段考前复习物理学史精编.doc

站在三星,以及其它大公司背后的韩国家族.docx

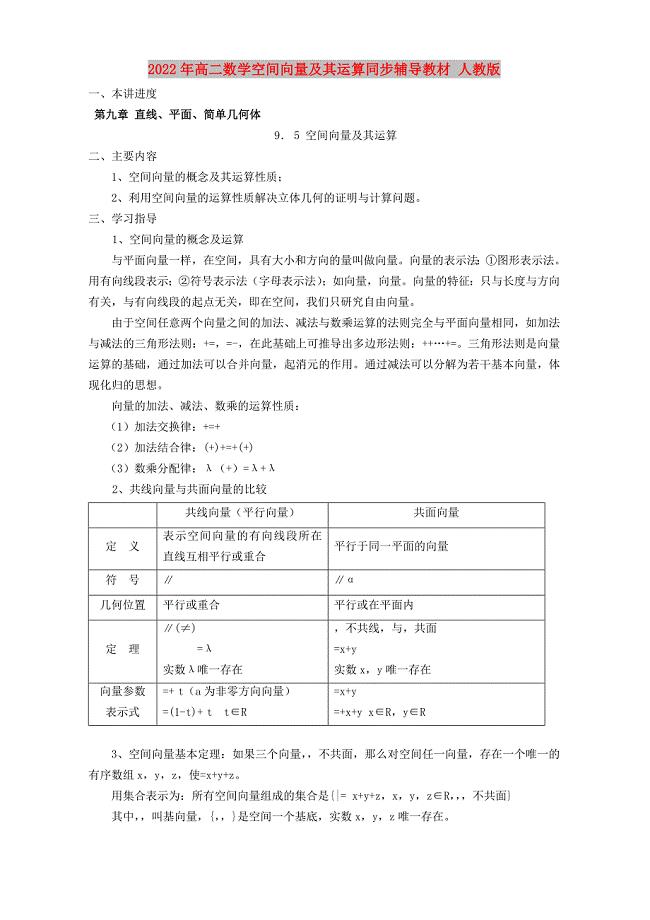

2022年高二数学空间向量及其运算同步辅导教材 人教版

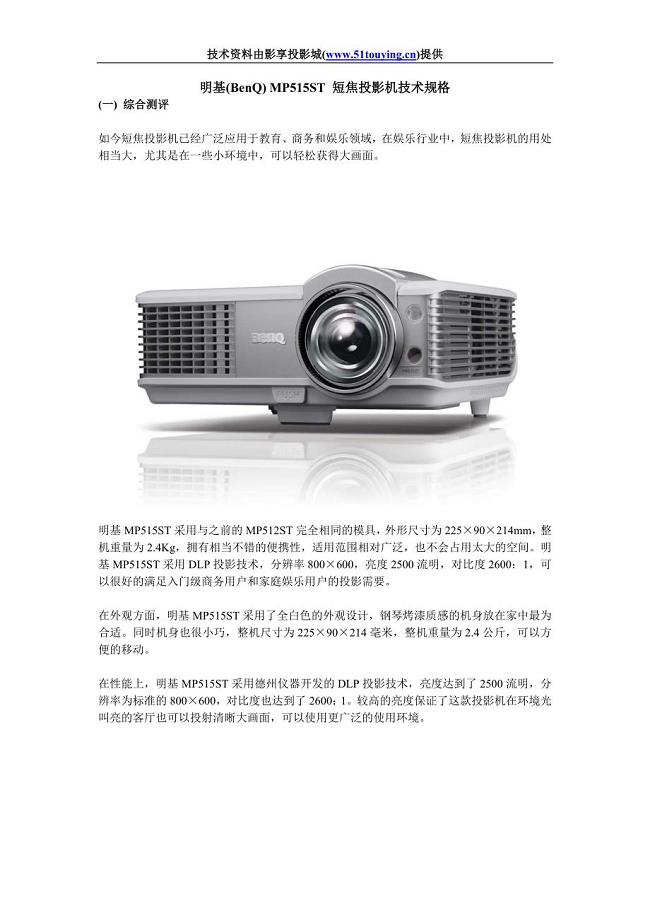

明基(BenQ)MP515ST教育投影机.doc

2022年路政员年终工作总结.docx

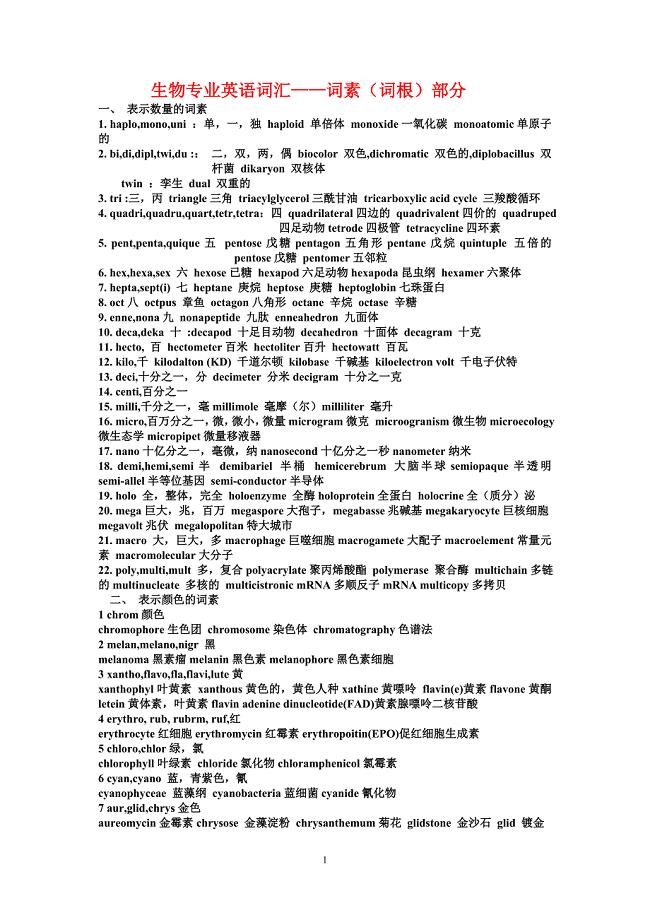

生物专业英语词汇——词素(词根)部分.doc

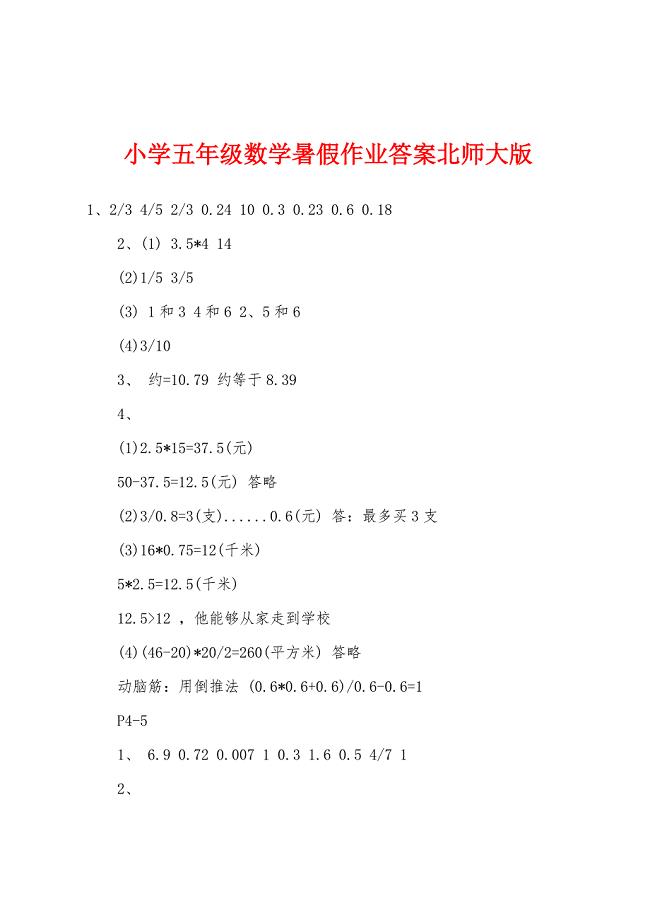

小学五年级数学暑假作业答案北师大版.docx

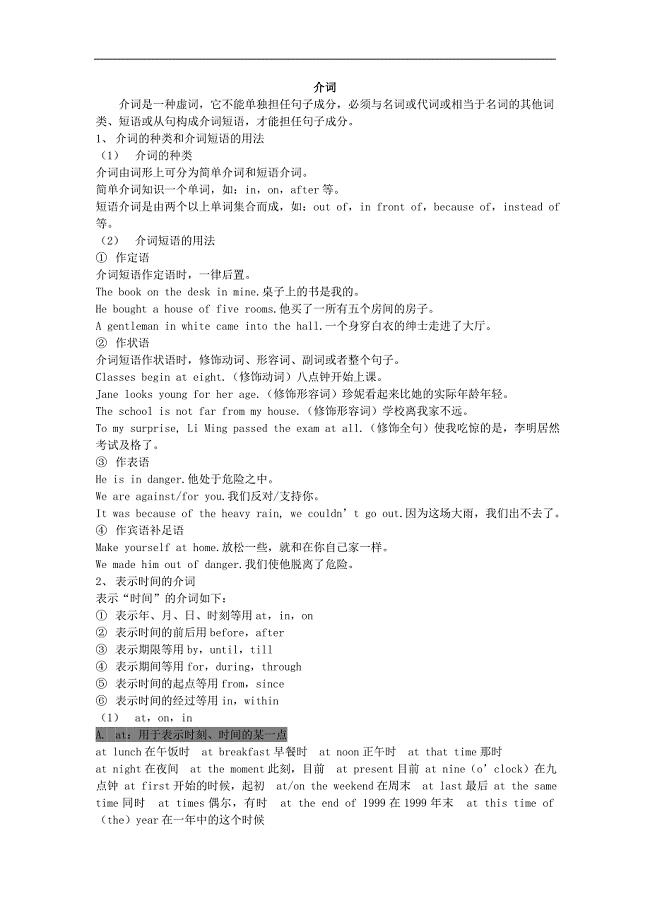

初中英语语法之介词讲解——英语中考专题复习

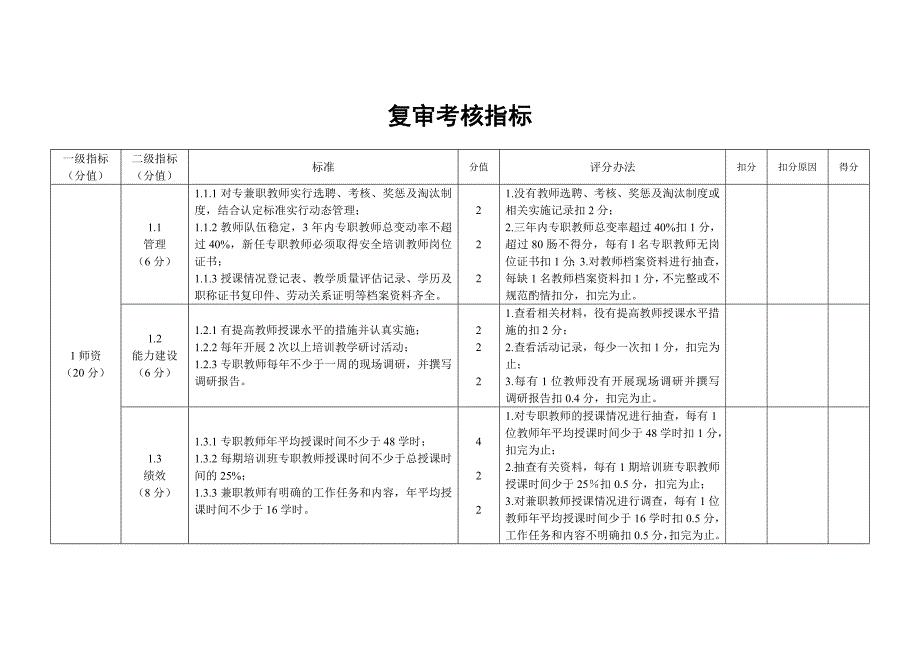

三级安全机构复审考核指标.doc

带圈的数字1至20

带圈的数字1至20

2024-02-03 3页

生活垃圾填埋场课程设计(榆林环11级)

生活垃圾填埋场课程设计(榆林环11级)

2022-09-03 6页

江苏省盐城市2021届高三下学期5月第三次模拟考试 英语(含答案)

江苏省盐城市2021届高三下学期5月第三次模拟考试 英语(含答案)

2022-09-18 13页

最新药品不良反应报告表

最新药品不良反应报告表

2023-03-06 1页

隔震结构设计实例

隔震结构设计实例

2023-01-23 7页

鞋款设计师基本知识

鞋款设计师基本知识

2024-02-21 8页

箱包手袋皮具出格设计QC基础知识

箱包手袋皮具出格设计QC基础知识

2023-12-24 6页

设计交底、图纸会审与技术交底的区别

设计交底、图纸会审与技术交底的区别

2022-11-11 5页

解决问题课件设计意图

解决问题课件设计意图

2023-11-06 4页

链板式输送机的设计计算

链板式输送机的设计计算

2023-02-08 11页