冲压模具毕业设计英文原文和汉语翻译(完整版)

15页1、Heat Treatment of Die and Mould Oriented Concurrent Design LI Xiong,ZHANG Hong-bing,RUAN Xueyu,LUO Zhong hua,ZHANG Yan Abstract: Many disadvantages exist in the traditional die design method which belongs to serial pattern. It is well known that heat treatment is highly important to the dies. A new idea of concurrent design for heat treatment process of die and mould was developed in order to overcome the existent shortcomings of heat treatment process. Heat treatment CAD/CAE was integrated with

2、 concurrent circumstance and the relevant model was built. These investigations can remarkably improve efficiency, reduce cost and ensure quality of R and D for products. Key words:die design; heat treatment; mould Traditional die and mould design,mainly by experience or semiexperience,is isolated from manufacturing process.Before the design is finalized,the scheme of die and mould is usually modified time and again,thus some disadvantages come into being,such as long development period,high cos

3、t and uncertain practical effect.Due to strong desires for precision,service life,development period and cost,modern die and mould should be designed and manufactured perfectly.Therefore more and more advanced technologies and innovations have been applied,for example,concurrent engineering,agile manufacturing virtual manufacturing,collaborative design,etc. Heat treatment of die and mould is as important as design,manufacture and assembly because it has a vital effect on manufacture,assembly and

4、 service lifeDesign and manufacture of die and mould have progressed rapidly,but heat treatment lagged seriously behind themAs die and mould industry develops,heat treatment must ensure die and mould there are good state of manufacture,assembly and wearresistant properties by request. Impertinent heat treatment can influence die and mould manufacturing such as overhard andsoft and assemblyTraditionally the heat treatment process was made out according to the methods and properties brought forwar

《冲压模具毕业设计英文原文和汉语翻译(完整版)》由会员jiups****uk12分享,可在线阅读,更多相关《冲压模具毕业设计英文原文和汉语翻译(完整版)》请在金锄头文库上搜索。

建立安全生产长效机制-共创和谐平安输气管道

土石方爆破工程设计方案

康师傅百货商场制度汇编之退换货管理办法

庙头中学2012年中考百日誓师大会学生代表发言稿

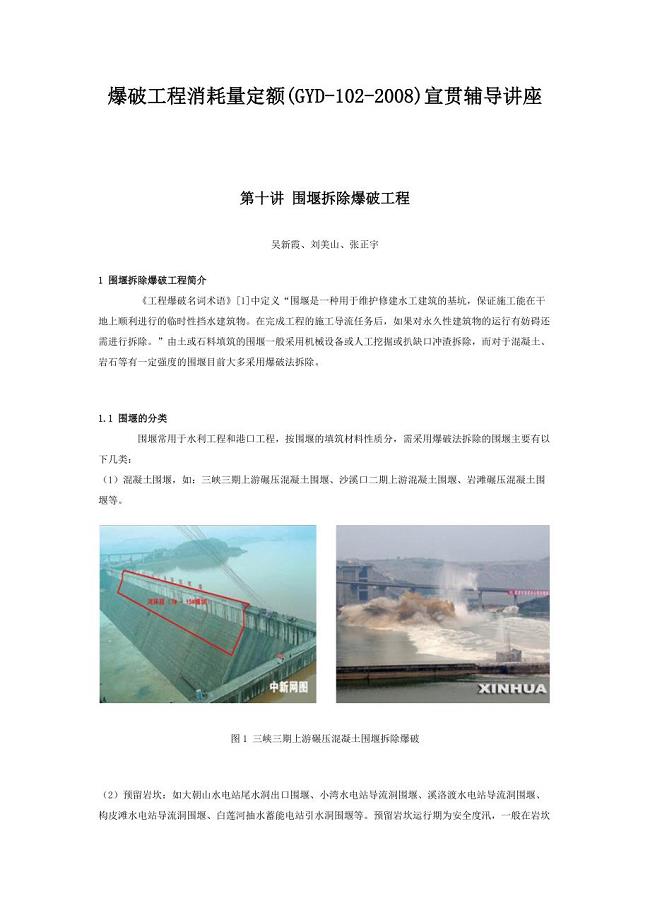

围堰拆除爆破工程

华能洱源马鞍山风电场工程土石方爆破管理制度

国资委:全面开展管理提升活动-为培育世界一流企业奠定坚实基础

《专业技术人员职业发展与规划》电子书

应收票据审计方案

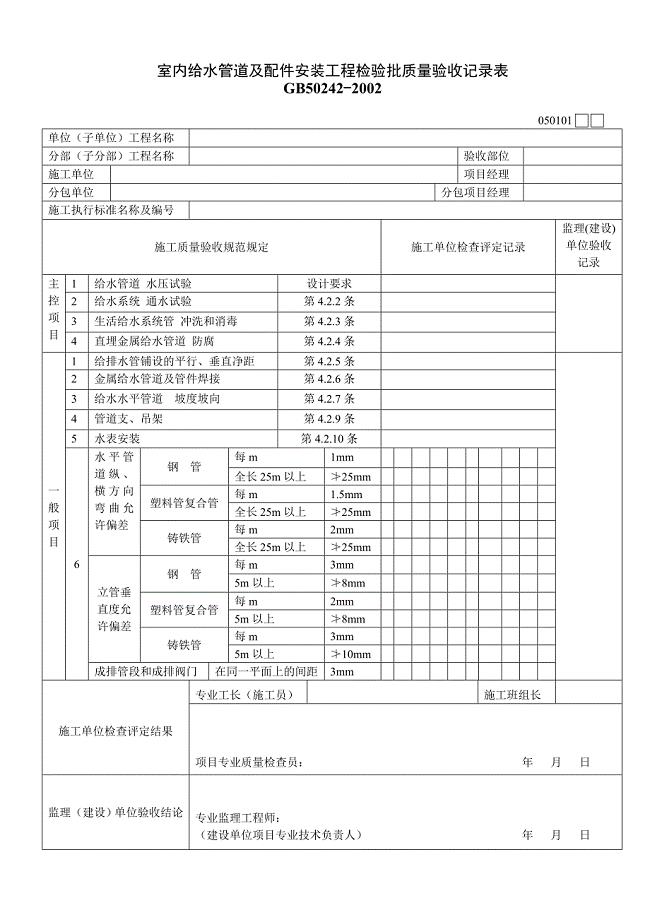

建筑给水排水与采暖工程质量验收用表

广播电视管理条例行政处罚裁量标准

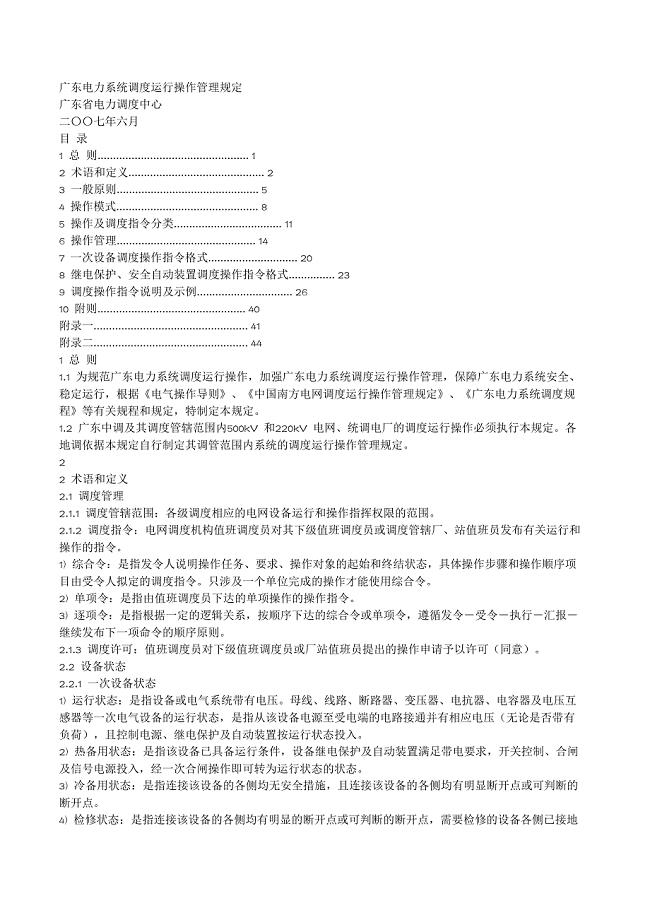

广东电力系统调度运行操作管理规定

建筑给排水工程名词解释

幼儿园小班安全健康活动教案:宝宝误食后的急救

建业集团房屋建筑工程交房标准内容技术交底

建筑心理学论文(1)

康师傅百货商场制度汇编之工服管理程序009

建筑工程专业一级建造师继续教育培训结业报告20

廉洁风险防控回头看工作汇报材料

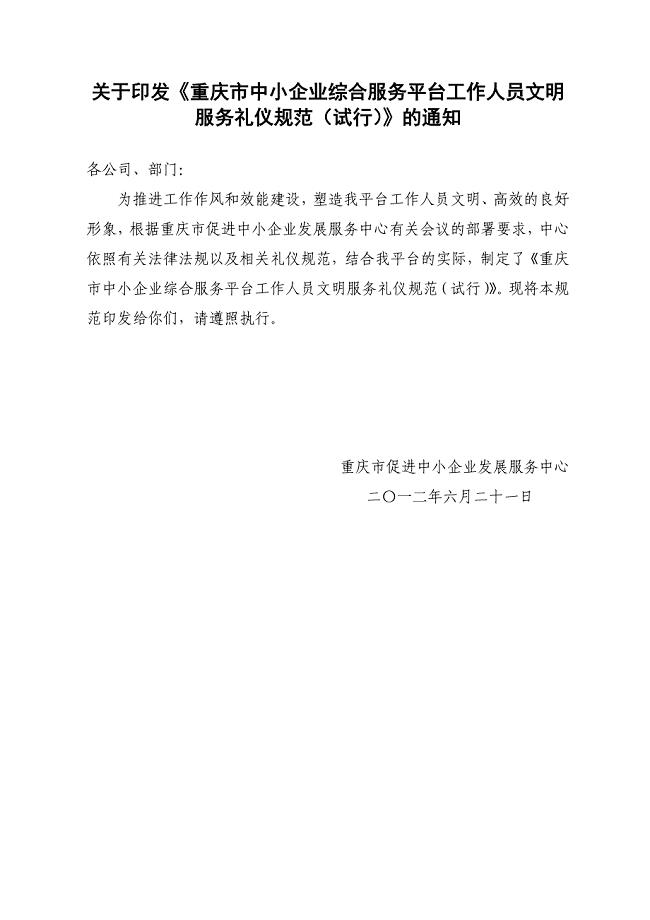

平台工作人员服务规范

2024年安徽省芜湖市中考二模语文试卷【含答案】

2024年安徽省芜湖市中考二模语文试卷【含答案】

2024-04-24 10页

2024届河北省邯郸市中考一模语文试题【含答案】

2024届河北省邯郸市中考一模语文试题【含答案】

2024-04-24 10页

2024年(6月份)中考数学押题试卷【含答案】

2024年(6月份)中考数学押题试卷【含答案】

2024-04-24 25页

2024年江苏省扬州市宝应县中考一模语文试题【含答案】

2024年江苏省扬州市宝应县中考一模语文试题【含答案】

2024-04-24 10页

辽宁省本溪市2022-2023学年高中下学期学业水平考试美术试题【含答案】

辽宁省本溪市2022-2023学年高中下学期学业水平考试美术试题【含答案】

2024-04-23 4页

第六单元 正比例和反比例 (单元测试卷)苏教版数学六年级下册【含答案】

第六单元 正比例和反比例 (单元测试卷)苏教版数学六年级下册【含答案】

2024-04-23 10页

江苏省无锡市2024年七年级下学期期中数学调研试卷【含答案】

江苏省无锡市2024年七年级下学期期中数学调研试卷【含答案】

2024-04-23 19页

江苏省江阴市华士片2022-2023学年七年级下学期期中语文试题【含答案】

江苏省江阴市华士片2022-2023学年七年级下学期期中语文试题【含答案】

2024-04-23 10页

江苏省泰州兴化市2023-2024学年高一下学期期中考试语文试题【含答案】

江苏省泰州兴化市2023-2024学年高一下学期期中考试语文试题【含答案】

2024-04-23 16页

小学六年级体育与健康测试题【含答案】

小学六年级体育与健康测试题【含答案】

2024-04-23 5页