制造工艺与质量控制(精)

7页1、Manufacturing Inspection Test Plan制造工艺与质量控制Client : Job No. Clients approval (用户批准)Approved byPlease approve this document by Jiangsu Kailai Steel Tube Co.,Ltd.江苏开来钢管有限公司DateJan 18, 2010 (Rev.0) Approved byChecked byPrepared byManufacturing Inspection Test PlanNoProcess 工艺Equipment & Operation 设备与操作Material Identification 材料标记Quality Control Procedure 质量控帽程序Scheduled date for Customers witness Remark By FWPM1IngotSA210 GR.A1/SA210 GR.C & (fully killed steel ) -SA210 GR.A1/SA210 GR.C 管坯必须是镇静钢 Rec

2、eiving -收料Identification on the raw material -确保管坯的标记准确Analysis of composition as per China National Standard-按照中国国家标准进行化学成分分析Two specimens of each Heat NO.-每个炉号取个试样“W”microstructure inspection ( Incl -foreign inclusions) as per China National Standard-按照中国国家标准进行低倍检验和非金属夹杂物检验Four specimens of each Heat NO.-每个炉号取个试样Visual and dimension inspection ,and grinding to remove the defect If necessary -,酸洗检查外表商,并根据需要修磨each Bar to be inspected -每支检查2Hot-Piercing-热穿孔Mandrel Shop -穿孔车间Putting traveling card

3、 on each Lot ( Heat No) -工艺流转卡标识内容完整Billet Cutting-断料As per work instruction -按照江苏开来钢管作业指导书“W”Control of Furnace temperature-炉温控制Checking and Recording temperature of Piercing-核对并记录穿孔温度piercing穿孔After hot swage ,Checking surface outside and inside condition and dimension热打头后,检查内外表面和尺寸Checking work No. and Heat No. Identification -检查工艺流转卡和炉号标识“W”3Mother tube Inspection -荒管检查Inspection and conditioning by grinder, if necessary -检查,根据需要修磨Putting traveling card process control card for cold-working

4、mill on each lot -完整 的工艺流转卡到冷拔 Visual inspection surface quality-检查荒管的表面质量As per work instruction -按照江苏开来钢管作业指导“W” Recording of Inspection results.-记录检查的结果4Preparation for cold-drawn -冷拔准备Descaling and lubricating -酸洗,磷化和皂化Comparing number of tubes and traveling card-检查对比钢管与流转卡Inspection of surface defect of mother hollow, do the grinding if necessary.酸洗后进行毛管表面检查, 根据需要进行修磨.As per work instruction -按照江苏开来钢管作业指导“W”Control of concentration and temperature of solution and dipping time-酸洗与皂化控制5Cold-d

《制造工艺与质量控制(精)》由会员jiups****uk12分享,可在线阅读,更多相关《制造工艺与质量控制(精)》请在金锄头文库上搜索。

建立安全生产长效机制-共创和谐平安输气管道

土石方爆破工程设计方案

康师傅百货商场制度汇编之退换货管理办法

庙头中学2012年中考百日誓师大会学生代表发言稿

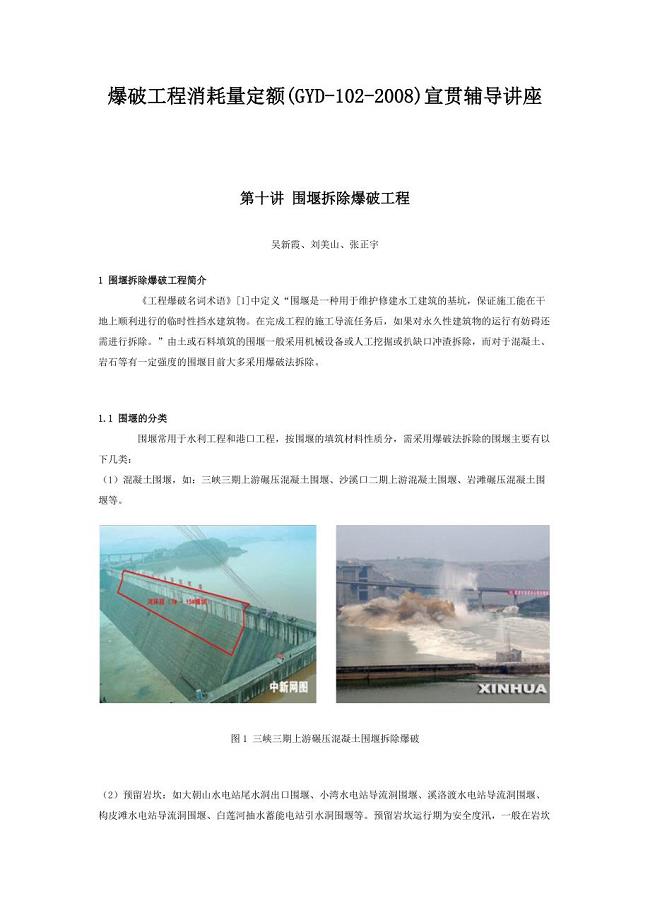

围堰拆除爆破工程

华能洱源马鞍山风电场工程土石方爆破管理制度

国资委:全面开展管理提升活动-为培育世界一流企业奠定坚实基础

《专业技术人员职业发展与规划》电子书

应收票据审计方案

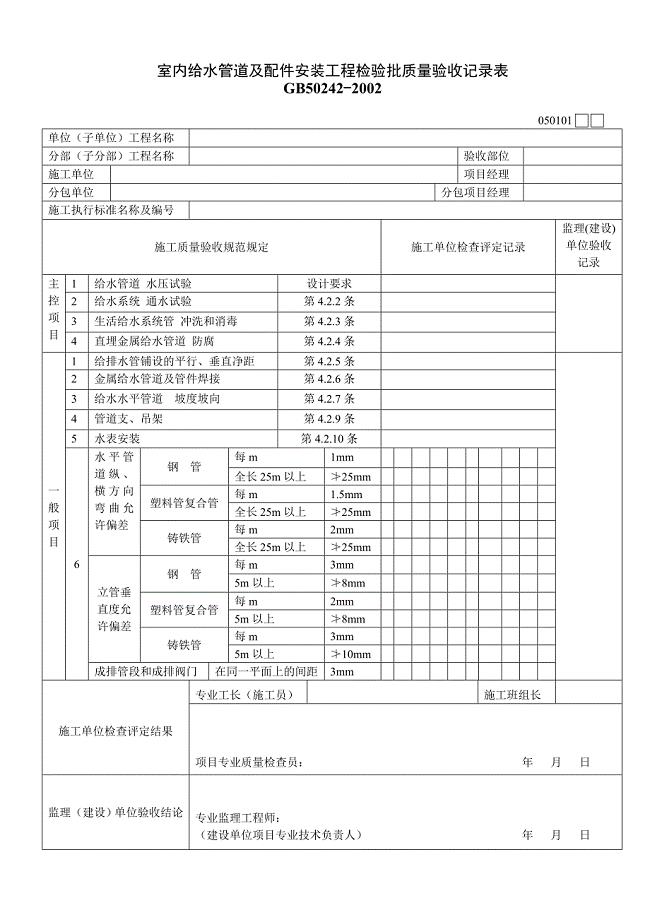

建筑给水排水与采暖工程质量验收用表

广播电视管理条例行政处罚裁量标准

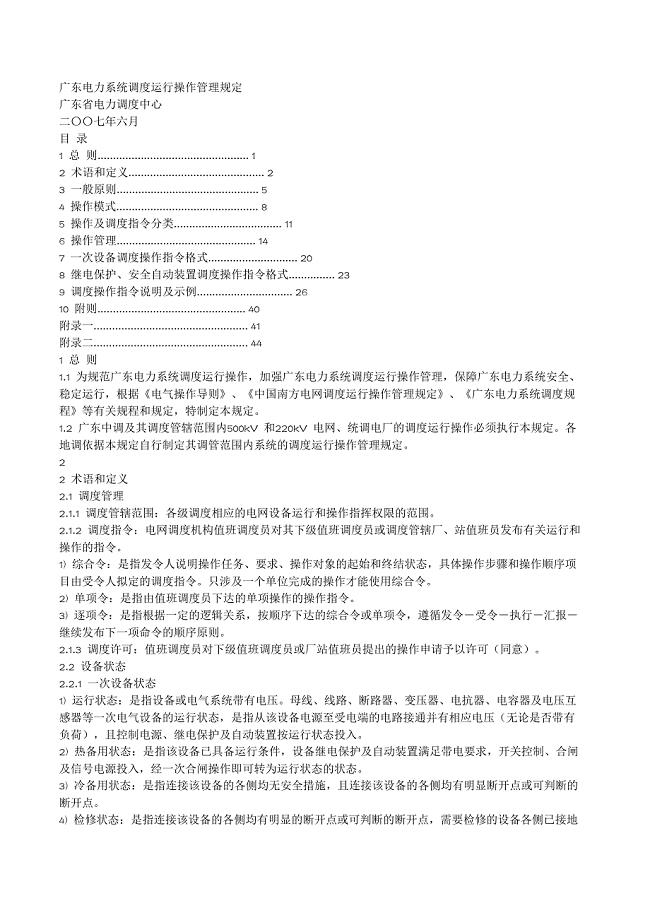

广东电力系统调度运行操作管理规定

建筑给排水工程名词解释

幼儿园小班安全健康活动教案:宝宝误食后的急救

建业集团房屋建筑工程交房标准内容技术交底

建筑心理学论文(1)

康师傅百货商场制度汇编之工服管理程序009

建筑工程专业一级建造师继续教育培训结业报告20

廉洁风险防控回头看工作汇报材料

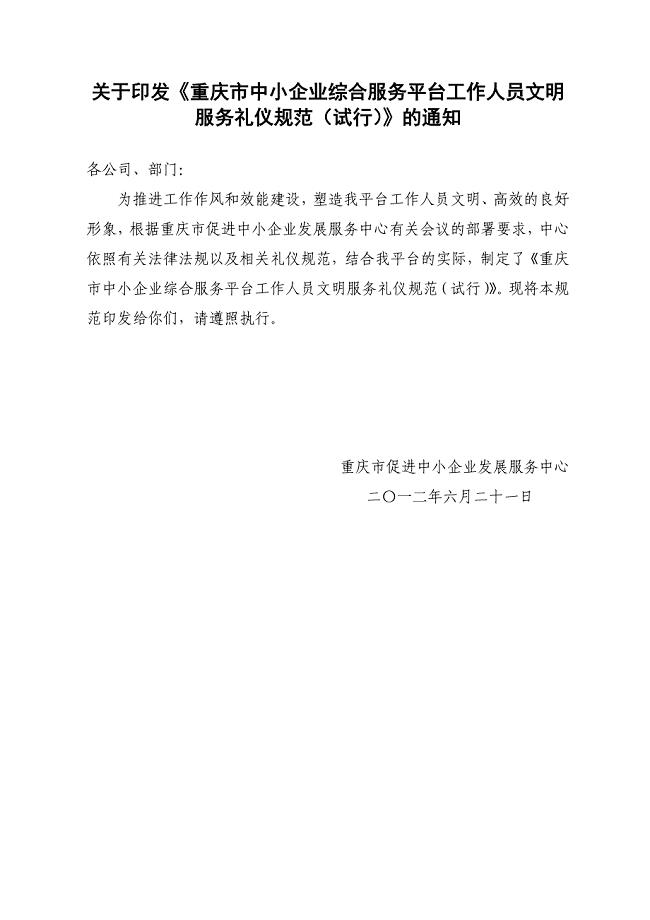

平台工作人员服务规范

2024年安徽省芜湖市中考二模语文试卷【含答案】

2024年安徽省芜湖市中考二模语文试卷【含答案】

2024-04-24 10页

2024届河北省邯郸市中考一模语文试题【含答案】

2024届河北省邯郸市中考一模语文试题【含答案】

2024-04-24 10页

2024年(6月份)中考数学押题试卷【含答案】

2024年(6月份)中考数学押题试卷【含答案】

2024-04-24 25页

2024年江苏省扬州市宝应县中考一模语文试题【含答案】

2024年江苏省扬州市宝应县中考一模语文试题【含答案】

2024-04-24 10页

辽宁省本溪市2022-2023学年高中下学期学业水平考试美术试题【含答案】

辽宁省本溪市2022-2023学年高中下学期学业水平考试美术试题【含答案】

2024-04-23 4页

第六单元 正比例和反比例 (单元测试卷)苏教版数学六年级下册【含答案】

第六单元 正比例和反比例 (单元测试卷)苏教版数学六年级下册【含答案】

2024-04-23 10页

江苏省无锡市2024年七年级下学期期中数学调研试卷【含答案】

江苏省无锡市2024年七年级下学期期中数学调研试卷【含答案】

2024-04-23 19页

江苏省江阴市华士片2022-2023学年七年级下学期期中语文试题【含答案】

江苏省江阴市华士片2022-2023学年七年级下学期期中语文试题【含答案】

2024-04-23 10页

江苏省泰州兴化市2023-2024学年高一下学期期中考试语文试题【含答案】

江苏省泰州兴化市2023-2024学年高一下学期期中考试语文试题【含答案】

2024-04-23 16页

小学六年级体育与健康测试题【含答案】

小学六年级体育与健康测试题【含答案】

2024-04-23 5页

广东省建筑装饰工程竣工验收技术资料统一用表

广东省建筑装饰工程竣工验收技术资料统一用表 水基防锈剂配方组成比例,防锈原理及配制方法

水基防锈剂配方组成比例,防锈原理及配制方法 辩论赛宁要大城市一张床,宁要小城镇一间房

辩论赛宁要大城市一张床,宁要小城镇一间房 【2018年整理】动力气象吕美仲课后答案.pdf

【2018年整理】动力气象吕美仲课后答案.pdf 红楼梦后28回(癸酉本)

红楼梦后28回(癸酉本) 金锄头网企业认证授权书(负责人非法人必须提供)

金锄头网企业认证授权书(负责人非法人必须提供) 服装设计助理实习周记

服装设计助理实习周记 制造机械项目投资分析报告(总投资15000万元)(78亩)

制造机械项目投资分析报告(总投资15000万元)(78亩) 计算机网络技术基础 教学课件 作者 阚宝朋 课件 第2章 网络体系结构与网络协议

计算机网络技术基础 教学课件 作者 阚宝朋 课件 第2章 网络体系结构与网络协议 计算机网络技术基础 教学课件 作者 阚宝朋 课件 第5章 网络层与网络互联

计算机网络技术基础 教学课件 作者 阚宝朋 课件 第5章 网络层与网络互联 计算机网络技术基础 教学课件 作者 阚宝朋 课件 第1章 网络基础知识

计算机网络技术基础 教学课件 作者 阚宝朋 课件 第1章 网络基础知识 输煤管道生产建设项目可行性研究报告

输煤管道生产建设项目可行性研究报告