模具设计与制造专业英语 教学课件 ppt 黄义俊_ 电子教案统一模板(模具)Unit3

25页1、Unit 3 The Plastic Mold Design,Unit 3 The Plastic Mold Design,3.1 Lesson 6 Plastics and Classification of Plastics,Plastic means pliable or impressionable. It is defined as the capability of being deformed continuously in any direction without breaking apart.1 Following this definition,plastics could include glass, metals, and waxThus, it is evident that name plastics is misleading and not exactly correctToday, however, the name plastics is identified with the products which are derived from syn

2、thetic resins. The synthetic resins are made by various chemical processesPlastics manufacturing is of comparatively recent date.,Today plastics are commonly found in homes, automobiles, numerous other products and machines. Some machines which utilize electricity require plastic parts with electrical insulating properties. Plastics are usually shipped to manufacturing plants as pellets or powders, and they are melted (for thermoplastics ) just before the shaping process. Plastics are also avail

3、able as sheet, plate, rod, and tubing, which may be formed into a variety of products.2 Liquid plastics are used especially in the making of reinforced plastic parts. Plastics or polymers, commonly called plastics, fall into two broad classes:, Thermoplastic molding materialsThese include polymers such as ABS and polycarbonate used for toys, consumer electronic products, and more flexible kitchenware products.3 The key feature is that these plastics can be heated to a viscous fluid, molded, and

4、cooled in a reversible, time-and time-again manner. Because the thermoplastic materials are those which soften with heating and solidify and harden with cooling, they can be remelted and cooled time after time without undergoing any appreciable chemical change., Thermosetting molding materials These include the melamine-formaldehyde used in hard plastic tableware and the epoxy resins used for glues and rein-forced cast products such as kayaks and tennis racket frames. Thermosetting products are

《模具设计与制造专业英语 教学课件 ppt 黄义俊_ 电子教案统一模板(模具)Unit3》由会员E****分享,可在线阅读,更多相关《模具设计与制造专业英语 教学课件 ppt 黄义俊_ 电子教案统一模板(模具)Unit3》请在金锄头文库上搜索。

逍遥游复习 知识点整理

近现代法德关系史 高三展示课3稿

当代大学生人生信仰及追求的调查研究

长相思 纳兰性德-ppt课件

课件:危机意识 一

英语ppt演讲关于阿甘正传

发达国家基础教育改革的动向与趋势 修改版

中国民间美术 课件.ppt

生物质发电技术与系统 课程ppt 第1章 生物质发电技术现状及发展趋势 2学时 -----2016

现代信号处理思考题 含答案

执业药师继续教育 抑郁症的药物治疗 100分

小学生的成长档案模板不用修改 万能型

增订六版 现代汉语 上册 第二章文字 思考与练习答案

国家财政ppt课件

加拿大英语介绍

六年级统计图的选择课件

中学生成长档案ppt

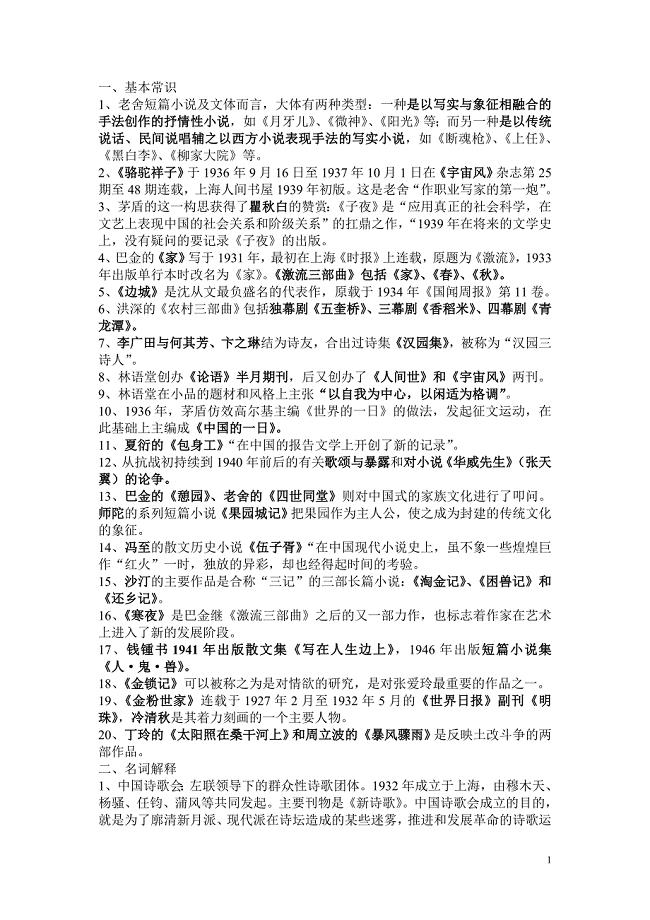

中国现代文学史期末复习整理

lohi和hihilo训练对女子赛艇运动员运动能力影响的比较研究

风雨贾平凹阅读答案

应对行业变革挑战策略

应对行业变革挑战策略

2024-04-11 25页

应对经济环境变化的策略布局(资料)

应对经济环境变化的策略布局(资料)

2024-04-11 37页

并购重组项目总结与反思

并购重组项目总结与反思

2024-04-11 28页

年度财务审计报告解读(资料)

年度财务审计报告解读(资料)

2024-04-11 31页

年度品牌影响力报告(资料)

年度品牌影响力报告(资料)

2024-04-11 36页

市场趋势分析与预测会议

市场趋势分析与预测会议

2024-04-11 29页

市场调研报告及趋势预测(资料)

市场调研报告及趋势预测(资料)

2024-04-11 22页

市场调研中的伦理与法律问题

市场调研中的伦理与法律问题

2024-04-11 27页

市场营销趋势与消费者行为分析会议

市场营销趋势与消费者行为分析会议

2024-04-11 34页

市场营销扩大商业影响力

市场营销扩大商业影响力

2024-04-11 32页