缸体图纸-REQ- CYLINDER BLOCK

3页1、Profile (specifications) needed to purchase machining line of cylinder block 1. Target of the project: Formation, Construction and design of cylinder blocks machining line capable of machining two kind of( eruo4+ tiba) engine cylinder blocks. 2. Production Capacity: The annual production capacity: 400000 cylinder blocks. 3. Process Machining process involves the following steps: 3.1. Inputs control 3.2. Preliminary machining 3.3. The washing step (Among stage) 3.4. Assembly of Caps 3.5. Final ma

2、chining 3.6. The washing step (Among stage) 3.7. Honing 3.8. Final washing & deburring 3.9. Assembly of cap seals 3.10. Final measurement, grade and classification 4. Ambient (environmental) conditions 4.1. Two shifts working (long working), 20 working hours per day 4.2. 265 working days per year 4.3. Working temperature is between 5 to 40 C 4.4. Three phases current 380-400 V, 50 HZ & rural current 220 V 4.5. Maximum of ambient sound level, 78 db 4.6. Air Pressure: 7 bar 5. Production lines fea

3、tures 5.1. Line type: transfer 5.2. One year warranty after installation and 10 years service after sales 5.3. Dust absorption & reduction system in accordance with ISO14000 & OHSAS standards 5.4. Full automatic production system with error announced scheme, troubleshooting software & error elimination system 5.5. Includes control systems during the production process and end of lines controlling systems, recording of information with providing of SPC 5.6. Adjustment of the production lines for

4、different products at the lowest possible time 5.7. Utilize of control systems (PLC, Siemens model) 5.8. Full list of spare parts should be presented (Obtainable & accessible) 5.9. All programs for machinery machining (with attention to workstations) should be provided 5.10. All applications and backup of all software (Like PLC) should be provided 5.11. All documents must be in English and also should be provided in hardcopy (paper base) and softcopy (CD) form 5.12. All machinery and equipment m

《缸体图纸-REQ- CYLINDER BLOCK》由会员206****923分享,可在线阅读,更多相关《缸体图纸-REQ- CYLINDER BLOCK》请在金锄头文库上搜索。

人教版小学英语单词分类记忆汇总表excel版

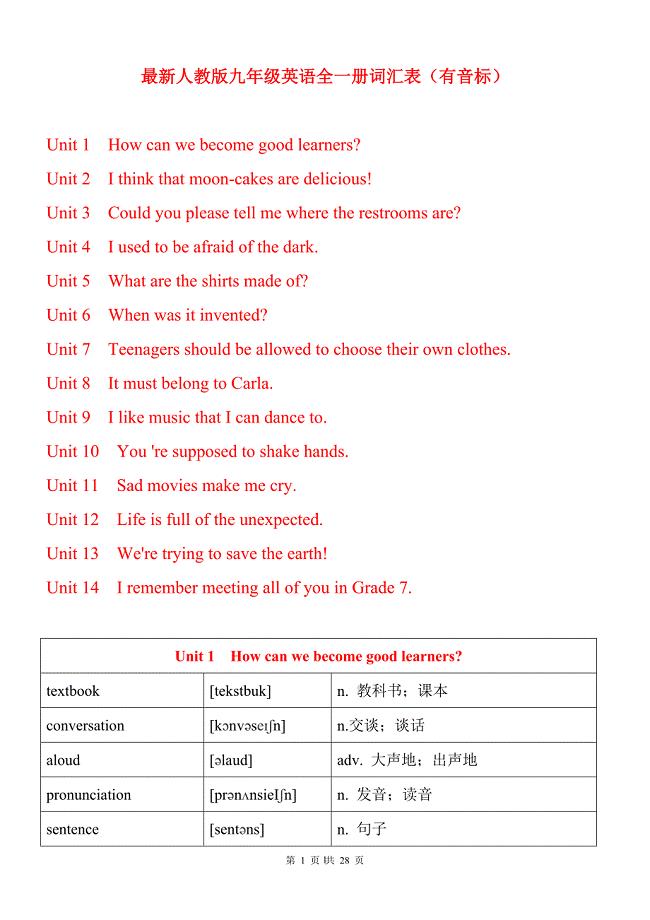

人教版九年级全一册英语词汇

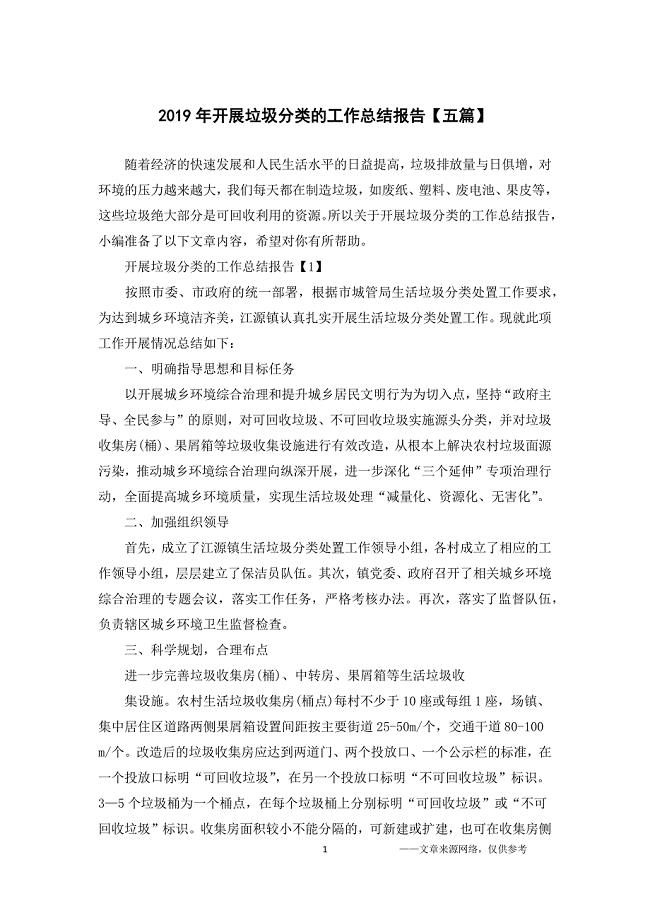

2019年开展垃圾分类的工作总结报告【五篇】

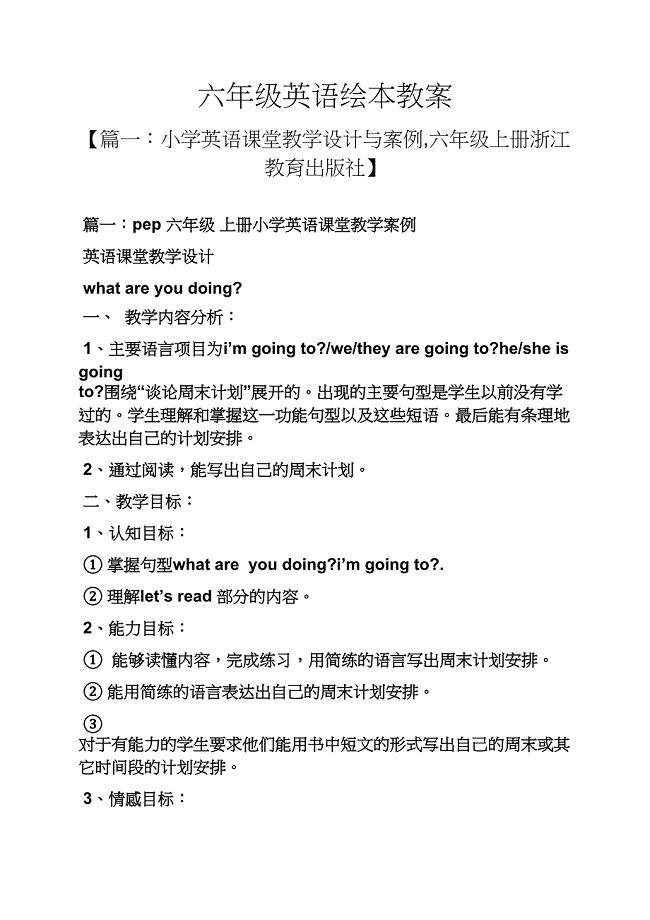

六年级英语绘本教案

外研版小学英语单词表全带音标(一年级起点1-12册)

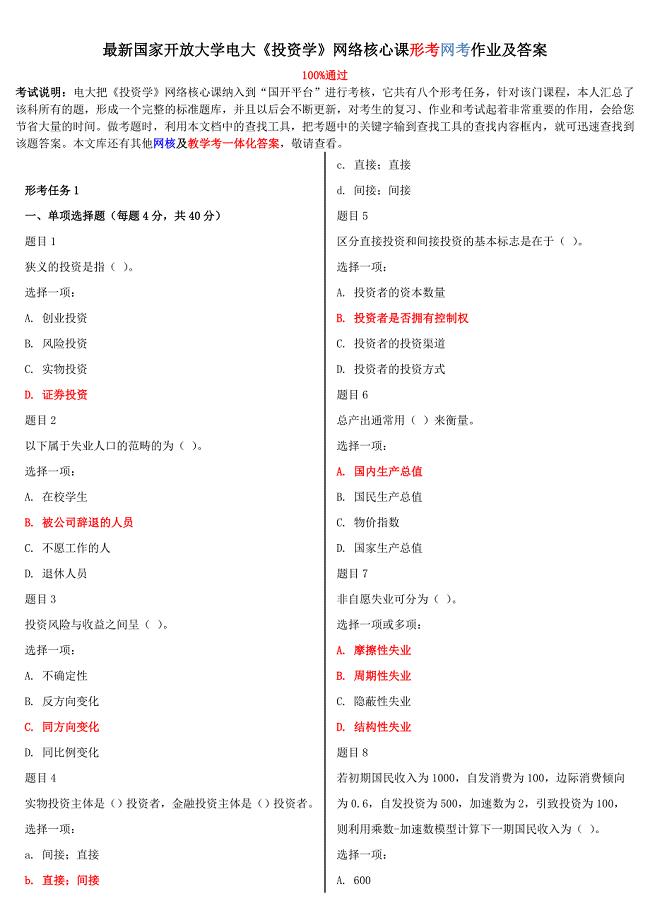

最新国家开放大学电大投资学网络核心课形考网考作业及答案

初中人教版七年级下册生物复习提纲

高中英语语法大全高中英语语法系统全解word版

☆初中英语语法专项练习习题以及答案

初中英语常考近义词同义词辨析

高中物理选修3-5全套教案(人教版) (1)

英语绘本《WeatherReport》教学设计

防护功能平战转换设计专篇各专业

初中人教版七年级上册下册全册生物复习提纲21页 (1)

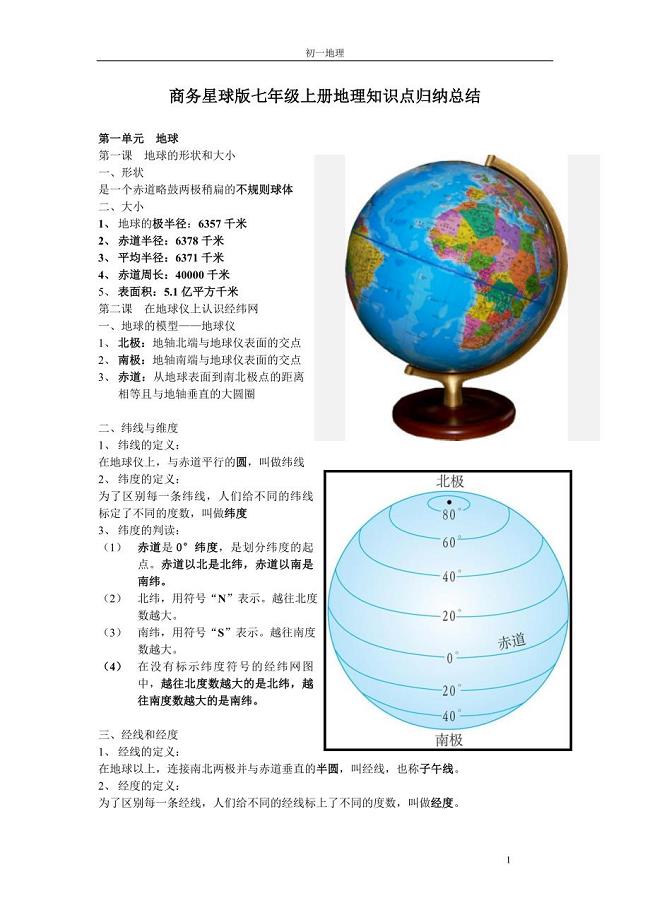

商务星球版七年级上册地理知识点归纳总结

初中人教版七年级上册下册全册生物复习提纲21页 (2)

高中高考语文作文词汇句型优美句子万能语句大全

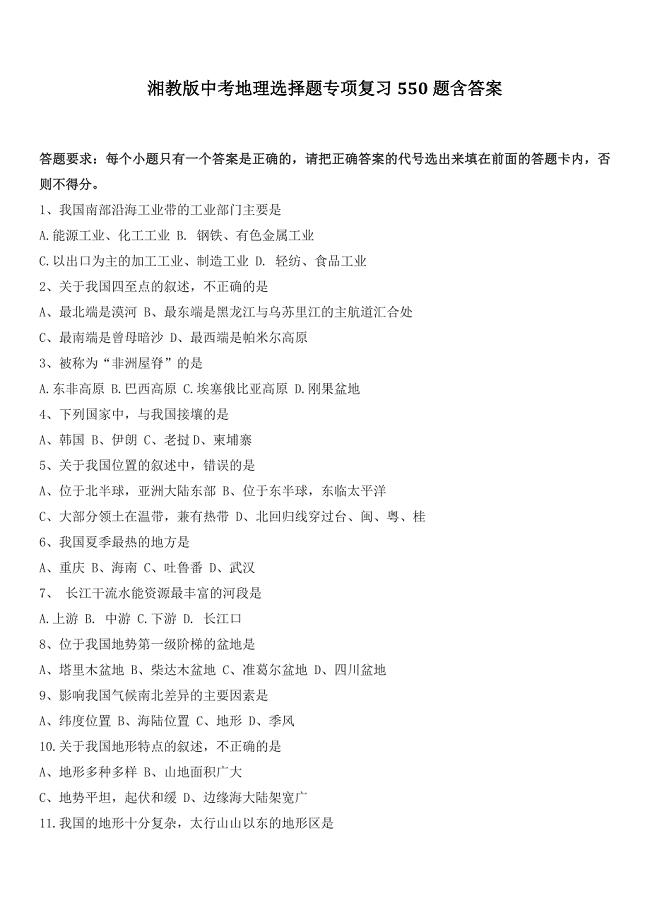

中考地理选择题专项复习550题含答案

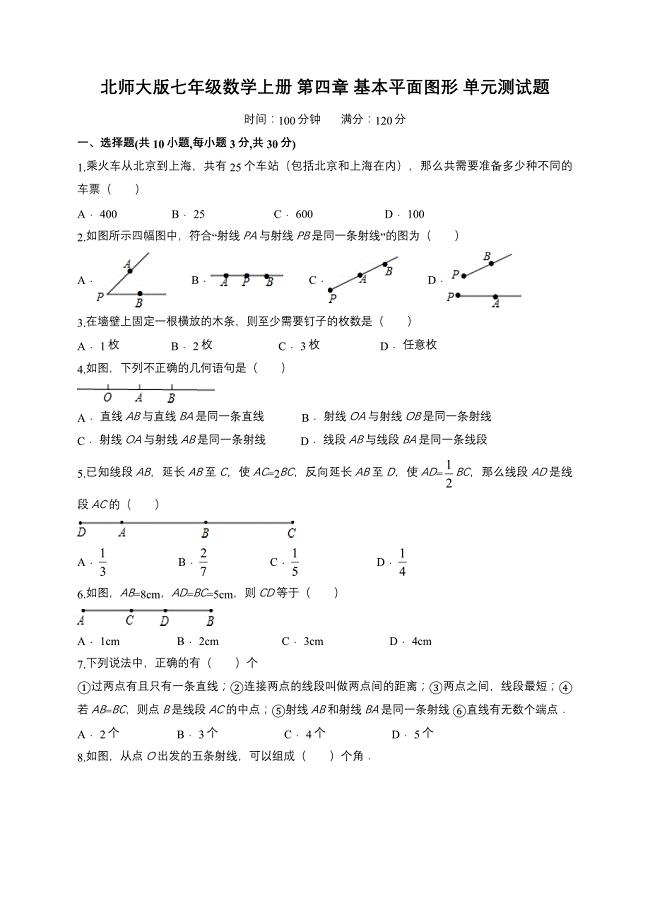

北师大版七年级数学上册第四章基本平面图形单元测试题含解析

人教版七年级数学上册第一章有理数单元检测题解析版

部品入厂检验标准(电子烟五金类)

部品入厂检验标准(电子烟五金类)

2024-04-24 8页

部品入厂检验标准(烟油类)

部品入厂检验标准(烟油类)

2024-04-24 1页

部品入厂检验标准(电芯类)

部品入厂检验标准(电芯类)

2024-04-24 1页

部品入厂检验标准(电子烟硅、橡胶类)

部品入厂检验标准(电子烟硅、橡胶类)

2024-04-24 1页

环境有害物质培训考核试题+答案

环境有害物质培训考核试题+答案

2024-04-24 3页

电子烟塑胶件入厂检验品质标准

电子烟塑胶件入厂检验品质标准

2024-04-24 8页

来料检验程序(电子烟)

来料检验程序(电子烟)

2024-04-24 5页

怀化市怀铁二中中小学生防震减灾知识竞赛题库

怀化市怀铁二中中小学生防震减灾知识竞赛题库

2024-04-23 12页

品烟师兼测试工程师岗位说明书

品烟师兼测试工程师岗位说明书

2024-04-23 5页

IQC组长岗位说明书

IQC组长岗位说明书

2024-04-23 4页